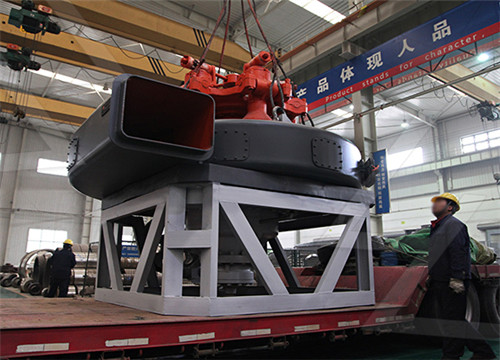

Vibrating Feeder Lignite Sulawesi

Vibrating Feeder Design StockpileReclaim General Kinematics

Advantages of Vibrating Feeders. Vibratory feeders are basically applied to a control function to meter or control the flow of material from a

Vibrating feeder Schenck Process

Schenck Process vibrating feeders are preferably used for discharging bulk solids from silos. They transport medium to large material flows over conveyor routes of varying

进一步探索

Used Conveyors Vibratory Feeders for Sale Surplus RecordVibrating Feeder Design StockpileReclaim General Kin根据热度为您推荐•反馈

Eriez Vibratory Feeders and Conveyors

Our Heavy Duty Electromagnetic Vibratory Feeders are ideal for handling coal, ore, aggregates, slag—or any other situation where high volume, controlled feeding is

Vibratory Feeders Coperion

The K3 vibratory feeders have a modular design and are available in both a standard design and a hygienic easy clean design. Vibratory feeders are ideal for gentle handling of a wide range of bulk solid materials,

Feeder-Breakers McLanahan

McLanahan Feeder-Breakers come in a variety of configurations and designs for use underground and above. They are particularly useful in underground and open pit mining

VIBRATING FEEDER 911Metallurgist

2021年5月8日Electric Vibrating Feeder. The Electric Vibratory Feeder is a vibrator that provides an extremely efficient, simple and economical solution to the problem of making the most stubborn material flow

AViTEQ: Vibrating feeder

Vibratory feeders are capable of conveying a wide range of particle sizes. Designed to be robust, either of an open or enclosed trough design. The trough-shaped structure are

Vibrating Feeder Applied Vibration

A common use of a vibrating feeder is in filling applications where the electromagnetic drive operates at maximum amplitude to rapidly fill a weighed container. As the target weight is reached, the feed rate is

Vibratory Feeders Eriez

Vibratory Feeders; Facebook LinkedIn Please wait while we gather your results. 15A Electromagnetic Feeder. The smallest AC feeder in the line, this economical model will

Eriez Vibratory Feeders and Conveyors

Our Heavy Duty Electromagnetic Vibratory Feeders are ideal for handling coal, ore, aggregates, slag—or any other situation where high volume, controlled feeding is required. With their energy-saving intermeshed AC/permanent magnet drive, these powerful units are the workhorses in Eriez' huge stable of Vibratory Feeders and Conveyors.

Feeder-Breakers McLanahan

McLanahan Feeder-Breakers come in a variety of configurations and designs for use underground and above. They are particularly useful in underground and open pit mining of coal, lignite, salt, gypsum and other friable minerals and in the processing of coke from delayed coker units. Feeder-Breakers can accept large feed lumps of friable minerals

Vibrating Feeders General Kinematics

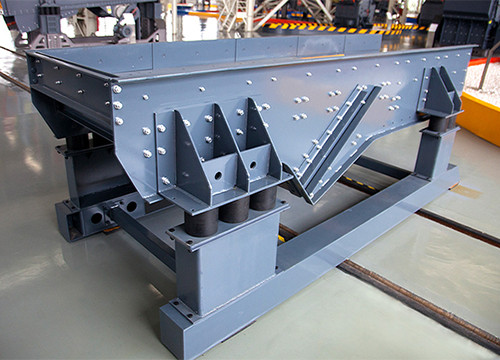

Vibrating Feeders General Kinematics Two-Mass Vibratory Feeders are ruggedly designed for the most demanding applications. This load responsive design takes on even the most challenging material load surges to keep your process flowing smoothly. The low maintenance high uptime design alleviates maintenance headaches and increases

Syntron Material Handling Products

Syntron Material Handling provides material handling solutions for conveying, feeding, screening, elevating, vibratory flow aids, and mining controls of bulk pr Heavy-Duty Feeders . Electromagnetic Feeders. Electromechanical. SYNTRO-FLO. HD Feeder Controls. Vibrating Screens

Study on Vibratory Feeders: Calculation of Natural

6. Natural Frequency of a Bowl-Type Vibratory Feeder 6.1 Fixed type vibratory feeder. In this type, the base of the feeder is attached to a foundation without a vibration isolator as shown in Fig. 1(d), so the vibratory system can have one-degree of freedom. The natural frequency of this type is expressed by 0 30 60 90 INCLINATION OF SPRING deg

VIBRATING FEEDER 911Metallurgist

2021年5月8日The vibratory feeder consists of a feed chute (which may be an open pan or closed tube) that is moved back and forth by the oscillating armature of an electromagnetic driver. The flow rate of the solids can be controlled by adjusting the current input into the electromagnetic driver of the feeder.

Vibratory Feeders — Performance Feeders Performance Feeders

Vibratory bowl feeders are the most versatile small parts orienting feeder on the market today. Built with standard components and custom-tooled to meet the needs of your application, our vibratory feeders are able to feed many different types of parts and can meet complex orientation requirements.

Vibrating Feeder Applied Vibration

A common use of a vibrating feeder is in filling applications where the electromagnetic drive operates at maximum amplitude to rapidly fill a weighed container. As the target weight is reached, the feed rate is slowed to a trickle until the

Vibrating feeder SlideShare

2015年2月11日Vibrating feeder 1. P R E P A R E D B Y J I S H N U V E N G I N E E R,B H E L I S G VIBRATING FEEDERS 2. 1.INTRODUCTION A vibrating feeder is a feeder/material conveying equipment consisting of a pan or trough to which a vibrating motion is imparted so that the material is impelled in a definite, controlled flow. Normally,

How do electromagnetic vibratory feeder works MP Elettronica

The vibration of an electromagnetic feeder is generated as the alternating electrical current moves back and forward through the wires of the coil. As the current moves in one direction, the coil attracts the magnet and adds tension to the springs. When the current switches direction the magnet is released, and the potential energy stored as

Vibratory Parts Feeding Systems Automation Devices

Generally, a vibratory drive unit, vibratory feeder bowl, amplitude controller and inline feeder and track are referred to as a vibratory parts feeder. A vibratory bowl is the bowl (tooled or untooled) that orients and feeds the parts when used with a vibratory drive unit. ADI offers two basic types of vibratory feeding systems:

Syntron Material Handling Feeder Controls

Syntron ® vibrating feeders are furnished with a standard control to vary the flow of material through the feeder by adjusting the amplitude of the feeder pan. Standard control units include an operating switch, fuse, and adjustable control to vary the amplitude. Simply connect the control box to an electrical source and to the electromagnetic vibrator or

Vibratory Feeders Grainger Industrial Supply

The feeder uses vibration to move the dispensed material at a consistent, controlled speed and volume into other processes or conveying systems. The control unit can be used to vary the amplitude (stroke size) of the vibratory feeder in order to change the rate that material flows from the feeder.

Feeder-Breakers McLanahan

McLanahan Feeder-Breakers come in a variety of configurations and designs for use underground and above. They are particularly useful in underground and open pit mining of coal, lignite, salt, gypsum and other friable minerals and in the processing of coke from delayed coker units. Feeder-Breakers can accept large feed lumps of friable minerals

Syntron Material Handling Products

Syntron Material Handling provides material handling solutions for conveying, feeding, screening, elevating, vibratory flow aids, and mining controls of bulk pr Heavy-Duty Feeders . Electromagnetic Feeders. Electromechanical. SYNTRO-FLO. HD Feeder Controls. Vibrating Screens

Study on Vibratory Feeders: Calculation of Natural

6. Natural Frequency of a Bowl-Type Vibratory Feeder 6.1 Fixed type vibratory feeder. In this type, the base of the feeder is attached to a foundation without a vibration isolator as shown in Fig. 1(d), so the vibratory system can have one-degree of freedom. The natural frequency of this type is expressed by 0 30 60 90 INCLINATION OF SPRING deg

Aggregates McLanahan

The Feeders are designed specifically for the application’s material size, weight and desired throughput, and then programmed to feed the aggregate at a set rate to match the capacity of a conveyor belt or crusher. Some are designed with the means to scalp the feed to filter out the undersized product. Types of Aggregate Feeders Apron Feeders

Syntron Material Handling Feeder Controls

Syntron® vibrating feeders are furnished with a standard control to vary the flow of material through the feeder by adjusting the amplitude of the feeder pan. Standard control units include an operating switch, fuse, and adjustable control to vary the amplitude.

How do electromagnetic vibratory feeder works MP Elettronica

The vibration of an electromagnetic feeder is generated as the alternating electrical current moves back and forward through the wires of the coil. As the current moves in one direction, the coil attracts the magnet and adds tension to the springs. When the current switches direction the magnet is released, and the potential energy stored as

Vibratory Feeders — Performance Feeders Performance Feeders

Vibratory bowl feeders are the most versatile small parts orienting feeder on the market today. Built with standard components and custom-tooled to meet the needs of your application, our vibratory feeders are able to feed many different types of parts and can meet complex orientation requirements.

Vibratory Parts Feeding Systems Automation Devices

Generally, a vibratory drive unit, vibratory feeder bowl, amplitude controller and inline feeder and track are referred to as a vibratory parts feeder. A vibratory bowl is the bowl (tooled or untooled) that orients and feeds the parts when used with a vibratory drive unit. ADI offers two basic types of vibratory feeding systems:

Vibrating feeder SlideShare

2015年2月11日Vibrating feeder 1. P R E P A R E D B Y J I S H N U V E N G I N E E R,B H E L I S G VIBRATING FEEDERS 2. 1.INTRODUCTION A vibrating feeder is a feeder/material conveying equipment consisting of a pan or trough to which a vibrating motion is imparted so that the material is impelled in a definite, controlled flow. Normally,

Tuning Eriez Small Vibratory Feeders Instructional Video

Rob Yandrick, Product Manager-Vibratory/Screening, talks about proper use of and tuning of an Eriez vibratory feeder.Eriez offers a complete line of vibrator...

Eriez Vibratory Feeders and Conveyors

With their energy-saving intermeshed AC/permanent magnet drive, these powerful units are the workhorses in Eriez' huge stable of Vibratory Feeders and Conveyors. They are available in nine models with capacities to 850 tons (765 MT) per hour*. (*Capacity is based on sand weighing 100 pounds per cubic ft. (1.6 metric tons per cubic meter)

Vibrating electromagnetic feeders Electromagnetic vibratory feeder

Electromagnetic vibrating feeders for heavy duties. CHARACTERISTICS. Capacities up to 1.600 tn/h. Materials and designs according to industry. Smooth and stable functioning. Instant manual or remote flow control. ZERO maintenance. Product care; high frequency / low amplitude. Manual or remote control of the flow.

Vibrating feeder Wikipedia

A vibratory feeder is an instrument that uses vibration to "feed" material to a process or machine. Vibratory feeders use both vibration and gravity to move material. Gravity is used to determine the direction, either down, or down and to a side, and then vibration is used to move the material. They are mainly used to transport a large number