Tin Ore Coal Ore Feeding Machine Chute Vibrating Feeder With Iso

Eriez Vibratory Feeders and Conveyors

Our Heavy Duty Electromagnetic Vibratory Feeders are ideal for handling coal, ore, aggregates, slag—or any other situation where high volume, controlled feeding is

进一步探索

Vibratory Bowl Feeders R.R. FisherCo. LtdUsed and Surplus Vibrating Conveyors JM Industrial根据热度为您推荐•反馈

High-Tech ore chute feeder For Productive Mining

Good Quality High Efficiency Vibrating Ore Chute Feeder With Small Capacity Price For Sale $1,000.00-$5,000.00 / set 1.0 set (Min. Order) 6YRS CN Supplier > Contact

VIBRATING FEEDER 911Metallurgist

2021年5月8日VIBRATING FEEDER Vibratory feeders are used in gravimetric feeding systems to handle solids with particles that are loo large to be handled by screw, rotary

Ore Feeder Chute Feeder Grizzly Feeder JXSC Machine

2018年2月7日The Main Components of Ore Feeder: 1-fan Regulating Gate; 2-feeding Trough Plate; 3-feeding plate; 4-roller; 5-crank Connecting Rod; 6-transmission device.

Feeder Machines Ore Feeder Equipment JXSC Mine

JXSC is a China Feeder machine manufacturers who produce and sell quarry feeder and ore feeder, such as vibrating feeder (crusher feeder), electromagnetic vibratory

Feeders — TypesApplications Best Feeder For Your

2018年8月1日The grizzly feeder is often used to feed primary jaw crushers. Vibrating Grizzly Feeders are heavy-duty, robust machines that can absorb large surge loads

4 Incredibly Useful Vibrating Feeders to Improve Your

2023年2月15日4. Magnetic feeder. The magnetic feeder is very popular in the production of grinding powder. It can control the feeding amount, achieve uniform feeding, and

Types of Small Ore Feeders Mineral Processing

2016年5月30日Plunger Ore Feeder The Plunger Ore Feeder includes a strong cast iron frame supporting a small welded steel hopper, and the plunger bearing. The unit is built

China Mineral Quantificationally Feeding Machine Through

Mineral Quantificationally Feeding Machine Through Electromechanical Hopper Vibrating Chute Feeder. 1.Introduction:A periodic and reciprocating feeding machine for large

Eriez Vibratory Feeders and Conveyors

Our Heavy Duty Electromagnetic Vibratory Feeders are ideal for handling coal, ore, aggregates, slag—or any other situation where high volume, controlled feeding is required. With their energy-saving intermeshed AC/permanent magnet drive, these powerful units are the workhorses in Eriez' huge stable of Vibratory Feeders and Conveyors.

High-Tech ore chute feeder For Productive Mining Alibaba

ISO/CE High Efficiency Vibrating Ore Chute Feeder with small capacity and low price. Ready to Ship High Capacity Feeding Equipment Mining Coal Chute Feeder For Stone Rock Mineral / set. 1 set (Min Order) 12YRS. CN. High Capacity 100Tph Mining Feeder Gold Processing Plant Quarry Plant Ore Feeding Machine Chute Feeder For Sale / set.

Eriez Vibratory Feeders and Conveyors

Our Heavy Duty Electromagnetic Vibratory Feeders are ideal for handling coal, ore, aggregates, slag—or any other situation where high volume, controlled feeding is required. With their energy-saving intermeshed AC/permanent magnet drive, these powerful units are the workhorses in Eriez' huge stable of Vibratory Feeders and Conveyors.

VIBRATING FEEDER 911Metallurgist

2021年5月8日VIBRATING FEEDER Vibratory feeders are used in gravimetric feeding systems to handle solids with particles that are loo large to be handled by screw, rotary-vane, or vertical-gate feeders, or in operations where the physical characteristics of the solid particles would be adversely affected by passage through these volumetric feeding

Design and characteristic analysis of vibration feeding system for coal

2020年12月18日The vibratory feeder is a forced vibrating system mostly used in industries to feed material from hoppers, bins, silos and storage piles to belt conveyors. It is used to control the feed rate of

Mining feeders for consistent control

Feeders to keep you in control of your process. When faced with material of different sizes and densities from dry and abrasive to wet and sticky you can count on our feeders to efficiently and consistently convey it to the next stage in your process. We provide feeder solutions for a variety of mineral processing applications, at the

Types of Feeders and Their Applications McLanahan

2021年2月9日Vibrating Pan Feeders are generally used to feed primary crushers in aggregate, mining and recycling applications, but they can also be used to feed grizzly feeders for removing material ahead of a crusher. These types of feeders feature pan sections along the deck of the feeder.

Feeder Machines Ore Feeder Equipment JXSC Mine

JXSC is a China Feeder machine manufacturers who produce and sell quarry feeder and ore feeder, such as vibrating feeder (crusher feeder), electromagnetic vibratory feeder, mining pendulum feeder, chute feeder, disk feeder. Vibrating Feeder Capacity: 30TPH-1200TPH Feeding size: ≤1000mm

Apron Feeders Mineral ProcessingMetallurgy

2016年5月31日A jaw crusher fed with an Apron feeder will increase capacity upto 40% by eliminating bridging and supplying a steady even feed. Photo shows shop assembly of a 24” x 36” Traylor Type M Jaw Crusher and a 36” x 12’-0” Traylor All-Steel Heavy Duty Apron Feeder. The Type M Crusher is built with a 50,000 pound TENSILE STRENGTH

CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND

Chute flow patterns are described and the application of chute flow dynamics to the determination of the most appropriate chute profiles to achieve optimum flow is illustrated. The influence of the flow properties and chute flow dynamics in selecting the required geometry to minimise chute and belt wear at the feed point will be highlighted. 1.

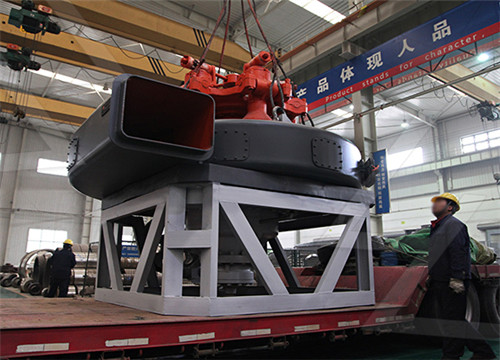

Mineral Feeding Chute, Gold, Tungsten, Tin Ore Feeding Machine

Mineral Feeding Chute, Gold, Tungsten, Tin Ore Feeding Machine, Find Details and Price about Vibrating Feeder Line Feeder from Mineral Feeding Chute, Gold, Tungsten, Tin Ore Feeding Machine Jiangxi Shicheng Yongsheng

Electromagnetic Vibrating Feeder JXSC Machine

Exclusive vibrating technology. 2. Small size and light in weight. 3. Simple structure, easy to install and use, low maintenance cost. 4. High efficiency and feeding capacity, high working frequency, and low electric consumption 5. Good operational reliability and

Vibration Chute Factory, Custom Vibration Chute OEM/ODM

Automatic Feeder Vibrating Grizzly Feeder with Good Price Unit Price: US$ 3000-3500 / Piece Min. Order: 1 Piece Add to Inquiry Basket 350mm Max Feeding Size Vibrating Grizzly Feeder From China 350mm Max Feeding Size Vibrating Grizzly Feeder From China Unit Price: US$ 3000-3500 / Piece Min. Order: 1 Piece Add to Inquiry Basket

Vibrating Feeder,feeding machine supplier walker mining

Vibrating feeder is a kind of equipment that can uniformly, regularly and continuously feed bulk and granular materials from the storage bin to the receiving device. It used both vibration and gravity to move material. Gravity is used to determine the direction and the vibration is used to move the material.

High-Tech ore chute feeder For Productive Mining Alibaba

Good Quality High Efficiency Vibrating Ore Chute Feeder With Small Capacity Price For Sale $1,000.00-$5,000.00 / set 1.0 set (Min. Order) 6YRS CN Supplier > Contact Supplier Chat Now 1 / 6 Vibrating chute feeder for stone crushing plant $1,999.00-$9,999.00 / set 1.0 set (Min. Order) 5YRS CN Supplier > Contact Supplier Chat Now 1 / 5

Eriez Vibratory Feeders and Conveyors

Our Heavy Duty Electromagnetic Vibratory Feeders are ideal for handling coal, ore, aggregates, slag—or any other situation where high volume, controlled feeding is required. With their energy-saving intermeshed AC/permanent magnet drive, these powerful units are the workhorses in Eriez' huge stable of Vibratory Feeders and Conveyors.

Design and characteristic analysis of vibration feeding system for coal

2020年12月18日The vibratory feeder is a forced vibrating system mostly used in industries to feed material from hoppers, bins, silos and storage piles to belt conveyors. It is used to control the feed rate of

Mining feeders for consistent control

Feeders to keep you in control of your process When faced with material of different sizes and densities from dry and abrasive to wet and sticky you can count on our feeders to efficiently and consistently convey it to the next stage in your process.

Mineral Feeding Chute, Gold, Tungsten, Tin Ore Feeding Machine

Mineral Feeding Chute, Gold, Tungsten, Tin Ore Feeding Machine, Find Details and Price about Vibrating Feeder Line Feeder from Mineral Feeding Chute, Gold, Tungsten, Tin Ore Feeding Machine Jiangxi Shicheng Yongsheng

Vibrating Feeder,feeding machine supplier walker mining

Motor vibrating feeder is an economical feeder with large capacity at present and it is widely used. According to the layout requirements of feeder users, it can be designed into sealed type and open type. The import and export

Apron Feeders Mineral ProcessingMetallurgy

2016年5月31日A jaw crusher fed with an Apron feeder will increase capacity upto 40% by eliminating bridging and supplying a steady even feed. Photo shows shop assembly of a 24” x 36” Traylor Type M Jaw Crusher and a 36” x 12’-0” Traylor All-Steel Heavy Duty Apron Feeder. The Type M Crusher is built with a 50,000 pound TENSILE STRENGTH

Vibrating Feeder Design StockpileReclaim General Kinematics

Advantages of Vibrating Feeders. Vibratory feeders are basically applied to a control function to meter or control the flow of material from a hopper, bin, or stockpile, much the same as an orifice or valve control flow in a hydraulic system. In a similar sense, feeders can be utilized as fixed rate, such as an orifice, or adjustable rate, as a

ISO 53.040.10 Conveyors International Organization for

90.93. ISO/TC 101. ISO 2406:1974. Continuous mechanical handling equipment — Mobile and portable conveyors — Constructional specifications. 90.93. ISO/TC 101. ISO 5041:1977. Continuous mechanical handling equipment for unit loads — Crate-carrying chain conveyors having biplanar chains for flat-bottomed unit loads — Safety code. 95.99.

Types of Small Ore Feeders Mineral ProcessingMetallurgy

2016年5月30日Plunger Ore Feeder The Plunger Ore Feeder includes a strong cast iron frame supporting a small welded steel hopper, and the plunger bearing. The unit is built so that a feed chute can be easily attached to the discharge opening. The stroke is adjustable and can be regulated easily. These ore feeders are low priced and recommended for

Weba Chutes To Optimise Silo ORE Flow For SA Gold Mine

2019年9月2日This allows the feed rate to be controlled by the Kwatani feeder, which has been integrated into the chute design.” The vibrating action of the feeder controls the tonnage and feed rate to the

Vibrating Grizzly Feeders ClassificationSeparation DOVE

DOVE Vibrating Grizzly Feeders, also referred to as Vibrating Grizzly Screens are highly efficient feeders designed to perform two major function of feeding ore into the next stage of the processing plant, as well as simultaneously separate and reject the oversize rocks.

Vibrating feeder Schenck Process

Schenck Process vibrating feeders are preferably used for discharging bulk solids from silos. They transport medium to large material flows over conveyor routes of varying length. Even very heavy, highly abrasive materials can be discharged under the most difficult of conditions with the aid of our specially designed vibrating feeders.

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日38%. Recovery rate. 74%. Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, High-strength magnetic separators. 07 150 TPH Bauxite ore beneficiation plant in Indonesia.

- Investment In Cement Brick Plant In India

- Professional Service Cement Grinding Mill Manufacturer

- 粘土砂处理工艺生产线厂家

- Tapper Lock 3020 Big Crusher Sheaves @ Pulley Catalo

- Gold Mining Equipment Agitator Flotation Machine

- 陕西蒲城破碎机厂址

- 邯郸哪里有石料加工得机器

- How To Build Gold Washing Shaker Machine

- 郑州万隆机械厂雷蒙磨

- 制砂生产线与石子生产线的对

- 民勤县龙瑞沙漠综合治理开发有限公司

- 移动颚破价格-矿石设备厂家价格

- 石粉厂家

- Crusher Classifier Sharing Tables India

- 如何办理采矿权审批手续