21492 Working Of Jaw Crushers

How A Jaw Crusher Works YouTube

根据热度为您推荐•反馈

® C Series™ jaw crushers Proven reliability

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher

How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

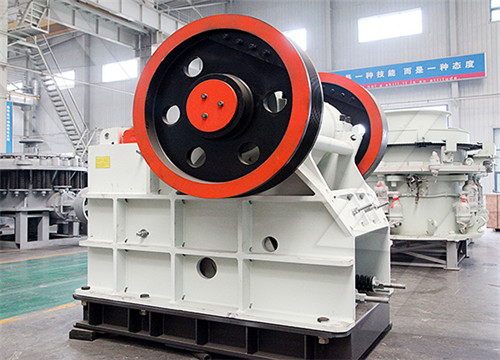

2022年6月8日All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped

What Is a Jaw Crusher? Here's How It Works Cutting

2021年2月18日All jaw crushers will have one fixed jaw and a moving one. These two form a V-shaped chamber, where the materials are fed. The movable jaw will move back and forth against the fixed one,

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a

Jaw Crusher Working Principle Animation YouTube

2019年1月18日5.75K subscribers Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates. There...

How does a Rock Crusher Work Jaw Crusher

2021年11月22日The 48 by 42-inch jaw crusher and smaller sizes are force-fed by an automatic high-pressure lubricator to the swing jaw, pitman, and main bearings as

What Are Jaw Crushers and How Do They Work? Oreflow

2019年3月28日How do jaw crushers work? Jaw crushers use compressive force to break down large materials into smaller, more manageable pieces. It has two crushing jaws (one is stationary while

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Additionally, jaw crusher feed should be pre-screened using a grizzly screen prior to crushing to remove material finer than the closed-side setting. Setting

Jaw Crushers

jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries. These crushers are

® C Series™ jaw crushers Proven reliability and

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

How Does a Jaw Crusher Work Jaw Crusher

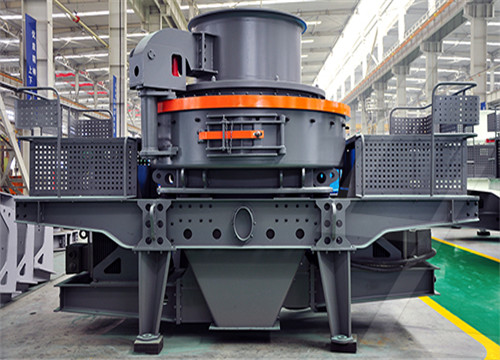

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical

Jaw crushers, Stationary Jaw crusher series — SRP

jaw crushers are reliable, high-performing crushers built to optimize primary crushing applications in mines and quarries. These tough crushers are delivered with everything you need for plug-and-play

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Jaw Crushers MEKA CrushingScreening Plants

JAW CRUSHER. Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are

Jaw Crushers Heavy Duty Finlay

The Finlay® J-960 is the most compact tracked jaw crusher in the ® Finlay range. This aggressive and versatile crusher is ideal for small scale on-site crushing of aggregates and construction demolition waste. The direct drive jaw chamber is fitted with an unblock feature that maximizes uptime. The machine features the robust 900mm

How does a Rock Crusher Work Jaw Crusher 911Metallurgist

2021年11月22日The 48 by 42-inch jaw crusher and smaller sizes are force-fed by an automatic high-pressure lubricator to the swing jaw, pitman, and main bearings as illustrated in Figure 1. A motor-driven pump forces the lubricant through pressure buildup cylinders and out to distributors which dispense a precise amount to each of the points on the bearings.

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日Gyratory Crushers typically have a higher capital cost and require a large housing structure that can become a significant engineering investment. Jaw Crushers. Jaw Crushers are another excellent choice

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Additionally, jaw crusher feed should be pre-screened using a grizzly screen prior to crushing to remove material finer than the closed-side setting. Setting jaw crushers. Ideally, the reduction ratio of a jaw crusher should be 6-to-1. There are different ways to calculate reduction ratio, but the best way is something called the P80 factor.

Used Jaw Crushers for Sale Surplus Record

- Kue Ken jaw crusher model 120S, Big Bite model, Double toggle jaw, 30/36 x 42 feed opening, Made in USA, Crusher RPM: 340, Motor available separately: 60 75 HP recommendedmore. View Details Contact Seller Request Price. Expand. 10 Photos. 35" x 43" #ST1109, Jaw Crusher.

Crusher an overview ScienceDirect Topics

A working cone crusher (Fig. 13.13) can perform as a tertiary crusher when installed in a close circuit between secondary crusher and ball mill to crush any overflow material of vibratory screening. Jaw crushers are installed underground in mines as well as on the surface. When used underground, jaw crushers are commonly used in open circuit.

Laboratory and pilot plant Primary Jaw Crushers

Essa JC1000 Jaw Crusher . The Essa JC1000 Jaw Crusher is the smallest of the range. It is a medium-duty, entry-level machine designed for crushing smaller samples across a wide range of applications. Known in the industry as a steady-going and reliable machine, it is productive and hardy, with reduced operating and spare parts costs.

Gyratory VS Jaw Crushers: AdvantagesDisadvantages

2016年2月28日Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation. The jaw crusher is more easily adjusted, to compensate for wear of liners.

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

® C Series™ jaw crushers Proven reliability and

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

How Does a Jaw Crusher Work Jaw Crusher

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on

Jaw crushers, Stationary Jaw crusher series — SRP

jaw crushers are reliable, high-performing crushers built to optimize primary crushing applications in mines and quarries. These tough crushers are delivered with everything you need for plug-and-play

Laboratory and pilot plant Primary Jaw Crushers

Essa JC1000 Jaw Crusher . The Essa JC1000 Jaw Crusher is the smallest of the range. It is a medium-duty, entry-level machine designed for crushing smaller samples across a wide range of applications. Known in the

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日Jaw Crushers are another excellent choice for primary crushing applications because they can accept the toughest, hardest, most abrasive materials. They can handle dry to slightly wet material that is

Gyratory VS Jaw Crushers: Advantages

2016年2月28日The jaw crusher, because of its box-frame construction, and simple toggle mechanism, is especially well adapted to extra heavy design for the crushing of extremely tough materials: in this respect it

Primary Crusher SelectionDesign Mineral

2015年12月23日Primary Crusher SelectionDesign.,degradability and it being prone to dusting or not. The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on

Used Jaw Crushers for Sale Surplus Record

Category: Jaw Crushers Seller: D'Angelo International Location: Bellingham, WA Mfr: Allis-Chalmers Double toggle jaw, Removed and dismantled, In storage, Bare jaw, no motor, A1 type machine, Feed opening: 42 x 48 inches, Throughput: 290-475 TPH, Closed side setting: 15-25more View Details Contact Seller Request Price 10 Photos

Jaw Crushers For Sale MyLittleSalesman

2023年3月6日Browse new and used Jaw Crushers For Sale near you. Find 94 Jaw Crushers by FABO, , Metso, McCloskey, Gator, and more on MyLittleSalesman. ENGINE HOURS

® C Series™ jaw crushers Metso Outotec

The core of ® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that

Jaw Crushers Heavy Duty Finlay

The Finlay® J-960 is the most compact tracked jaw crusher in the ® Finlay range. This aggressive and versatile crusher is ideal for small scale on-site crushing of aggregates and construction demolition waste. The direct drive jaw chamber is fitted with an unblock feature that maximizes uptime. The machine features the robust 900mm

Used Jaw Crushers for sale. equipmentmore Machinio

2014 Parker JR1165 Jaw Crusher USED Manufacturer: Parker Model: JR1165 Make: Parker Model: JR1165 Year: 2014 Hours: 3900+- Opening: 43”x 26” jaw Cross Belt Magnet: Yes This unit is in good operating order, as had good Maintenance and service. Have more pic if needed Location $218,500 USD Maryland, USA Click to Contact Seller

Jaw Crusher Premiertrak 400XR400X

The ® Premiertrak 400X range of portable jaw crushers are designed for medium scale operators in quarrying, demolition, recycling and mining applications. The range includes the Premiertrak 400X with hydraulic adjust and the Premiertrak R400X with hydraulic release. Working Dimensions: Width: 16'5" with side conveyor Length: 51