Mineral Ore Beneficiation Plant

Ore Beneficiation an overview ScienceDirect Topics

Rio Tinto Iron Ore's low-grade ore beneficiation plant in the Pilbara was commissioned in 1979. Initial engineering, design, and construction were undertaken by KBR (Kellogg

Flowsheet Development for Benefication of Lithium

2018年8月19日Sensor-based ore sorters can be effective in the rejection of iron -silicate minerals . These sorters are usually installed after the crushing plant, just upstream of

SGS MINERALS SERVICES T3 SGS 960 11-2009

SGS MINERALS SERVICES T3 SGS 960 11-2009 BENEFICIATION SGS MINERALS SERVICES’ EXPERTISE WITH BENEFICIATION Beneficiation is the process where

Titanium Beneficiation Plant Mineral Processing

titanium Beneficiation Titanium often occurs as oxide minerals. There are mainly ilmenite (FeTiO3), rutile (TiO2) and titanium magnetite that have industrial value utilization.

Mineral Beneficiation Plant Neon EngineeringMineral Company

Mineral Beneficiation Plant Extensive process plant experience covering the full range of recovery techniques and unit processes from ore beneficiation to final product.

Zircon Beneficiation Plant JXSC Mineral

Zircon Beneficiation Plant Zircon sand beneficiation is removing impurity minerals from zircon sand ore and increasing the content of zircon sand ore. We determine the

Mineral Beneficiation Plant Neon EngineeringMineral Company

• Iron Ore (Hematite)43% to 62%+, 19.5% to 63.2% • Manganese ore 18% to 38% KINC’s IOBP plant for iron ore beneficiation is milestone in a journey of excellence. Capable to

Iron Ore Beneficiation Mineral Processing

Iron Ore Processing Plant The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation,

Beneficiation Mining and Mineral Processing Equipment

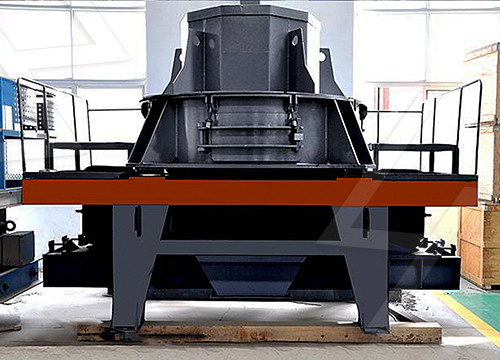

ZJH mainly focus on producing and supply crushers, ore grinding equipment, mineral beneficiation equipment, laboratory and pilot scale ore dressing equipment for Mining

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

2023年3月7日Mineral beneficiation technology is the fundamental solution to the tailing problem. An iron ore processing plant in Indonesia, for example, conducted magnetic separation on iron ore tailings

Ore Beneficiation an overview ScienceDirect Topics

OIA allows reliable and consistent identification of different iron oxide and oxyhydroxide minerals, e.g., hematite, kenomagnetite, hydrohematite, and vitreous and ochreous goethite, and many gangue minerals in iron ore and different ferrites and silicates in

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日In the early days of ore beneficiation, hand sorting was used to separate spodumene (Munson and (1981) the separation of spodumene from feldspar and quartz gangue minerals at Kings Mountain processing plant involves a de-sliming step that rejects −15 µm particles to waste during which 7.4 wt% feed assaying 1.43% Li 2 O is

Beneficiation Wikipedia

Beneficiation. In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product ( ore concentrate) and a waste stream ( tailings ). There are many different types of beneficiation, with each step

Titanium Beneficiation Plant Mineral Processing

titanium Beneficiation Process. 1. Gravity Separation. It is to remove the gangue minerals in the ore through jig concentrator, spiral chute,shaking table and other equipment after the raw ore is crushed. It is mainly suitable for coarse-grained embedded titanium and fine-grained collectively disseminated titanium. 2.

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日The various techniques used in the beneficiation of lithium minerals from hard rock pegmatite ores containing spodumene, petalite, lepidolite and amblygonite have been reviewed. Dense media separation and flotation are the main beneficiation methods used in many plants around the world. The success in separating lithium

Minerals Free Full-Text Economic and Socio-Environmental

2020年10月26日The concentration plant has a processing capacity of 8 the application of dry processing technologies in iron ore beneficiation is a topical area of Mineralogical analysis of the ore using QEMSCAN™ showed that the major iron-bearing minerals in the ore are magnetite (38%), goethite (16%), and hematite (5%). The major gangue

Zircon Beneficiation Plant JXSC Mineral

Zircon Beneficiation Plant Zircon sand beneficiation is removing impurity minerals from zircon sand ore and increasing the content of zircon sand ore. We determine the beneficiation process and equipment configuration according to the zircon placer’s specific mineral composition and properties.

Spodumene and lepidolite beneficiation method Prominer

2023年3月7日Spodumene and lepidolite beneficiation method. 03-07-23; 7 Views; icon 0; Lithium is an important raw material for energy supply. With the rapid rise of new energy sources, lithium ore resources have been pushed to a development boom.

Brand New Copper Gold Ore Flotation Separator Manufacturing Plant

Quality Brand New Copper Gold Ore Flotation Separator Manufacturing Plant Mineral Flotation Machine find quality Ore Beneficiation Machine, Mineral SeparatorOre Beneficiation Machine from Zhengzhou VANGUARD Machinery Technology Co., Ltd. of China Suppliers .

Nickel Ore Beneficiation Plant Mineral Processing

Nickel Ore Beneficiation Nickel ores mainly include copper-nickel sulfide ore and nickel oxide ore (laterite nickel ore). The most important is the nickel ore flotation process, magnetic separation and gravity separation are usually auxiliary beneficiation methods. Inquiry Now Nickel Ore Beneficiation Process 1. Copper-nickel sulfide ore

Iron ore beneficiation Commodities Mineral Technologies

The world’s largest producers rely on Mineral Technologies for iron ore processing solutions. From Canada’s Labrador Trough region, across India, Brazil and Africa, to Australia’s iron rich Pilbara, our teams deliver unrivalled expertise in fine iron ore beneficiation. Mineral Technologies can assist you to deliver a comprehensive range

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日38%. Recovery rate. 74%. Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, High-strength magnetic separators. 07 150 TPH Bauxite ore beneficiation plant in Indonesia.

Beneficiation of Iron Ore Mineral ProcessingMetallurgy

2016年5月24日Beneficiation of Iron Ore treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation.

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

2023年3月7日Mineral beneficiation technology is the fundamental solution to the tailing problem. An iron ore processing plant in Indonesia, for example, conducted magnetic separation on iron ore tailings

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日In the early days of ore beneficiation, hand sorting was used to separate spodumene (Munson and (1981) the separation of spodumene from feldspar and quartz gangue minerals at Kings Mountain processing plant involves a de-sliming step that rejects −15 µm particles to waste during which 7.4 wt% feed assaying 1.43% Li 2 O is

Titanium Beneficiation Plant Mineral Processing

titanium Beneficiation Process. 1. Gravity Separation. It is to remove the gangue minerals in the ore through jig concentrator, spiral chute,shaking table and other equipment after the raw ore is crushed. It is mainly suitable for coarse-grained embedded titanium and fine-grained collectively disseminated titanium. 2.

Beneficiation Wikipedia

Beneficiation. In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product ( ore concentrate) and a waste stream ( tailings ). There are many different types of beneficiation, with each step

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日The various techniques used in the beneficiation of lithium minerals from hard rock pegmatite ores containing spodumene, petalite, lepidolite and amblygonite have been reviewed. Dense media separation and flotation are the main beneficiation methods used in many plants around the world. The success in separating lithium

Minerals Free Full-Text Economic and Socio-Environmental

2020年10月26日The concentration plant has a processing capacity of 8 the application of dry processing technologies in iron ore beneficiation is a topical area of Mineralogical analysis of the ore using QEMSCAN™ showed that the major iron-bearing minerals in the ore are magnetite (38%), goethite (16%), and hematite (5%). The major gangue

Beneficiation Mining and Mineral Processing Equipment Supplier

ZJH mainly focus on producing and supply crushers, ore grinding equipment, mineral beneficiation equipment, laboratory and pilot scale ore dressing equipment for Mining and Mineral Processing Industry. Our aim is to work together with Mines, Mineral Beneficiation Plants for helping to reduce the operating cost ,to improve the operating efficiency.

Graphite Ore Beneficiation Mineral Processing

Graphite processing plant. The general graphite mining process flow includes crushing screening grinding flotation dehydration drying grinding grading, and packaging. 1. Preparatory process (crushing, screening and grinding) Since the hardness of graphite ore is generally medium-hard or medium-hard to soft, and the

Spodumene and lepidolite beneficiation method Prominer

2023年3月7日Spodumene and lepidolite beneficiation method. 03-07-23; 7 Views; icon 0; Lithium is an important raw material for energy supply. With the rapid rise of new energy sources, lithium ore resources have been pushed to a development boom.

Brand New Copper Gold Ore Flotation Separator Manufacturing Plant

Quality Brand New Copper Gold Ore Flotation Separator Manufacturing Plant Mineral Flotation Machine find quality Ore Beneficiation Machine, Mineral SeparatorOre Beneficiation Machine from Zhengzhou VANGUARD Machinery Technology Co., Ltd. of China Suppliers .

A review of the beneficiation of copper-cobalt-bearing minerals

2019年11月1日The ore sample used contained 2.03% Cu, 0.15% Co, and 3.73% S. The valuable minerals present were chrysocolla, chalcopyrite, and native copper. The gangue comprised pyrite, carbonate, calcite, and clay minerals. The ore (of a size up to −149 μm) was beneficiated using the sulphidisation and xanthate flotation method.

Nickel Ore Beneficiation Plant Mineral Processing

Nickel Ore Beneficiation Nickel ores mainly include copper-nickel sulfide ore and nickel oxide ore (laterite nickel ore). The most important is the nickel ore flotation process, magnetic separation and gravity separation are usually auxiliary beneficiation methods. Inquiry Now Nickel Ore Beneficiation Process 1. Copper-nickel sulfide ore

Iron ore beneficiation Commodities Mineral Technologies

The world’s largest producers rely on Mineral Technologies for iron ore processing solutions. From Canada’s Labrador Trough region, across India, Brazil and Africa, to Australia’s iron rich Pilbara, our teams deliver unrivalled expertise in fine iron ore beneficiation. Mineral Technologies can assist you to deliver a comprehensive range

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日A complete ore beneficiation plant has four stages: screening and crushing, mill grinding process, beneficiation process, and ore drying process. 2 Mill grinding process 3 Beneficiation process 4 Ore drying process 1 Screening and crushing 2 Mill grinding process 3 Beneficiation process 4 Ore drying process 1 Screening and