Raw Mill Roller Fl Atox

Long-lasting coal mill for efficient grinding

A compact coal mill solution for grinding virtually any type of raw coal. Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force

Vertical Roller Mills

根据热度为您推荐•反馈

: ATOX® raw mill YouTube

2013年2月26日This film demonstrates all aspects of the ATOX® raw mill: how it saves space and energy and why it has been proven to deliver reliable operation for

ATOX coal mill

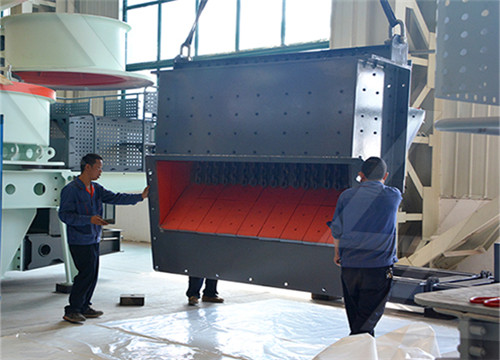

Changing of roller wear segments for smaller mills can alternatively take place outside the mill. For the ATOX 30 and smaller, the whole roller assembly can be pulled out on a

ATOX® animation for raw grinding YouTube

2013年2月26日 12.9K subscribers This is the ATOX movie for raw mill grinding in an animated version. Whether grinding raw coal, clinker, cement and/or slag, we have

Vertical roller mill ATOX® MAAG Gear AG compact

A compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill

Atox Raw Mill [PDF Document]

2014年11月2日The flexible ATOX raw mill can prepare virtually any kiln feed material to your required fineness in an energy-efficient process regardless of variations in

ATOX® Coal Mill G7 Equipment

The most durable coal mill for grinding all types of raw coal. Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal. The rollers work

Atox Raw Mill PDF Mill (Grinding) Bearing

The flexible ATOX raw mill can prepare virtually any kiln feed material to your required fineness in an energy-efficient process regardless of variations in grindability, drying requirements and abrasion. In fact, the ATOX can

Vertical roller mill services

ATOX® Coal Mill. Back. Hi-Chrome Wear Segments. Back. OK™ Pro+ Ceramic Wear Segments. Record-setting vertical roller mill exceeds performance guarantee for Shah Cement Services. Products; OK™ Raw and Cement Mill. ATOX® Coal Mill. Hydraulic Roller Press. Keep exploring. Stories from . News. 4 March 2021. 5,200m²

: ATOX® raw mill YouTube

2018年3月18日This film demonstrates all aspects of the ATOX® raw mill: how it saves space and energy and why it has been proven to deliver reliable operation for...

ATOX® animation for raw grinding YouTube

2013年2月26日 12.9K subscribers This is the ATOX movie for raw mill grinding in an animated version. Whether grinding raw coal, clinker, cement and/or slag, we have a vertical roller mill...

Download information about our products and solutions I

Reliable resources that drive productivity in cement and mining Materials produced by to help increase productivity and sustainability in the mining and cement industries. View or download brochures, case studies and more by using the search and filter options found below let our expertise lead the way to your continued growth.

ATOX mill split oil seal

27.5 to 52.5 ATOX raw mills. The conversion is a one-time investment: to install the conversion kit, the roller must be disassembled in the workshop. After converting to split seals, an inner oil seal replacement can be done with only 15 hours of mill downtime. This simplified procedure eliminates a kiln stop and excessive loss of lubrication oil,

ATOX® Coal Mill G7 Equipment

The most durable coal mill for grinding all types of raw coal. Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal. The rollers work harmoniously with a highly-efficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture level.

Atox Raw Mill [PDF Document]

2014年11月2日The flexible ATOX raw mill can prepare virtually any kiln feed material to your required fineness in an energy-efficient process regardless of variations in grindability, drying requirements and abrasion. In fact, the ATOX can be adapted to a wide variety of specific requirements.

flsmidth atox vertical mill MiningQuarry Plant

2013年5月23日ATOX raw mill. Vertical roller mills are widely accepted as the most efficient means of prepar Ball Mills. has over 100 years experience in Ball Mills.

Fls Atox Raw Mill

mill eHighlights. fl atox raw mill design trivenischool co in. ATOX raw mill . material composition of raw May 5th, 2018 Fls Atox Raw Mill Professional mining ? atox raw mill problems vertical roller mill fls Vertical roller mill is a new kind of large scale power mill which is designedspecially to solve the problems of low

atox raw mill lubrication

Grinding OK Vertical Roller Mill, ATOX Raw Mill, ATOX Coal Mill and ATOX Split Seal offered by Get More Information vertical roller mill in cement industry atox 45

Atox Raw Mill PDF Mill (Grinding) Bearing (Mechanical) Scribd

The flexible ATOX raw mill can prepare virtually any kiln feed material to your required fineness in an energy-efficient process regardless of variations in grindability, drying requirements and abrasion. In fact, the ATOX can be adapted to a

Atox Mill PDF Mill (Grinding) Bearing (Mechanical) Scribd

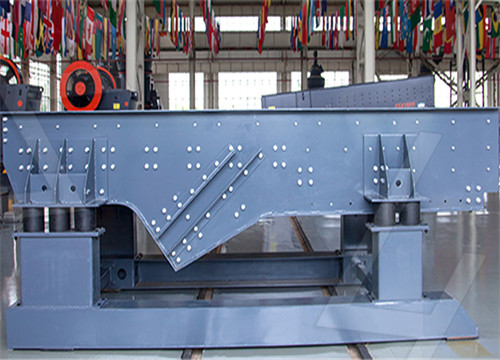

The ATOX raw mill is of a very compact design involving a space-saving arrangement of inlet ducts and, further, crane access for service is required in only one position. The ATOX mill is thus easy to fit into a constricted space.

Atox Mill Roller Assembly IndiaMART

Get Atox Mill Roller Assembly in Ambattur Industrial Estate, Chennai, Tamil Nadu at best price by R C Das Engineering Private Limited. Also find Roller Assembly price list from verified suppliers with contact number ID: The function of Atox Raw Mill uses pressure and shear generated between the rollers and the rotating table to

vertical millsfor raw and cement grinding inspection and evaluation

cement raw mill process.pdf, The raw mill shown in Figure is a vertical roller mill with an internal particle BALL MILL INSPECTION PROCEDURE The Cement Grinding Office. Go to Product Center. FL ATOX® Raw Mill FL One source supplier, The ATOX® raw mill uses pressure and shear generated

: ATOX® raw mill YouTube

2018年3月18日This film demonstrates all aspects of the ATOX® raw mill: how it saves space and energy and why it has been proven to deliver reliable operation for...

Download information about our products and solutions I

Reliable resources that drive productivity in cement and mining Materials produced by to help increase productivity and sustainability in the mining and cement industries. View or download brochures, case studies and more by using the search and filter options found below let our expertise lead the way to your continued growth.

ATOX® Coal Mill G7 Equipment

The most durable coal mill for grinding all types of raw coal. Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal. The rollers work harmoniously with a highly-efficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture level.

vertical millsfor raw and cement grinding inspection and evaluation

cement raw mill process.pdf, The raw mill shown in Figure is a vertical roller mill with an internal particle BALL MILL INSPECTION PROCEDURE The Cement Grinding Office. Go to Product Center. FL ATOX® Raw Mill FL One source supplier, The ATOX® raw mill uses pressure and shear generated

Atox Raw Mill [PDF Document]

2014年11月2日The flexible ATOX raw mill can prepare virtually any kiln feed material to your required fineness in an energy-efficient process regardless of variations in grindability, drying requirements and abrasion. In fact, the ATOX can be adapted to a wide variety of specific requirements.

Atox Raw Mill PDF Mill (Grinding) Bearing (Mechanical) Scribd

The flexible ATOX raw mill can prepare virtually any kiln feed material to your required fineness in an energy-efficient process regardless of variations in grindability, drying requirements and abrasion. In fact, the ATOX can be adapted to a

Atox Mill PDF Mill (Grinding) Bearing (Mechanical) Scribd

The ATOX raw mill is of a very compact design involving a space-saving arrangement of inlet ducts and, further, crane access for service is required in only one position. The ATOX mill is thus easy to fit into a constricted space.

flsmidth atox vertical mill MiningQuarry Plant

2013年5月23日ATOX raw mill. Vertical roller mills are widely accepted as the most efficient means of prepar Ball Mills. has over 100 years experience in Ball Mills.

atox raw mill lubrication

atox raw mill roller lubrication system ppt hydraulic system for fls raw mill crusher.quartz With the sealing air and roller lubrication system the roller bearings in the grinding rollers are hydraulic system for fls raw mill Get More

Fls Atox Raw Mill

mill eHighlights. fl atox raw mill design trivenischool co in. ATOX raw mill . material composition of raw May 5th, 2018 Fls Atox Raw Mill Professional mining ? atox raw mill problems vertical roller mill fls Vertical roller mill is a new kind of large scale power mill which is designedspecially to solve the problems of low

Atox Mill Roller Assembly IndiaMART

Atox Mill Roller Assembly Get Latest Price We are supplying Atox Mill Roller Assembly to M/S F.L.Smidth India Pvt. Ltd, Chennai for their Atox Raw Mill. The function of Atox Raw Mill uses pressure and shear generated between the rollers and the rotating table to crush and grind raw materials.

Pulverizer Coal Mill Structure ATOX KM 27.5

abon crusher parts Crusher Grinding Mill,CCM Manufacturer Abon CrusherPulverizing Equipment 2 km 15 Marshall Rd VIC Atox Coal Mill, Atox Raw the frame structure of the roller crusher comprises welded and

Analysis and solution of crack of ATOX50 raw material mill tie rod

2021年2月14日Line 2 of a company's raw material mill is ATOX50 roller mill, which was put into use in July 2007. There are three rollers, each roller is equipped with a pull rod head, as shown in Figure 1. The A end is connected with the piston rod of the hydraulic cylinder through the stretching rod, and the lifting of the grinding roller is

ATOX Raw Mill IndiaMART

The ATOX® raw mill uses pressure and shear generated between the rollers and the rotating table to crush and grind raw materials. Feed material is directed onto the grinding table by the feed chute. The rotation of the grinding table accelerates the material towards the grinding track and passes it under the rollers.