Vsi Crusher Balancing

Barmac VSI Rotor Balancing YouTube

2015年7月18日311 subscribers Correctly balancing the rotor of a Vertical Shaft Impact crusher prior to installation will reduce the amount of operational vibration. Reducing

Texas Crusher Systems, Inc.

根据热度为您推荐•反馈

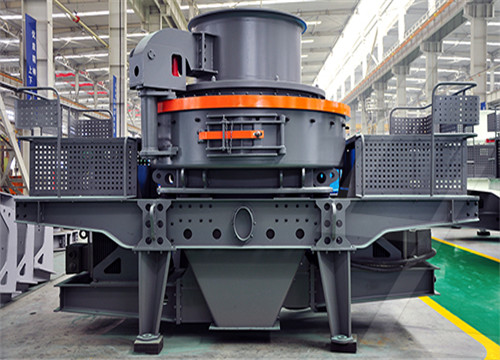

Stationary VSI impact crushers, VSI Crusher

VSI crushers can operate within an open circuit as well as a closed, with product gradation further controlled by the rotational speed of the rotor. It then goes through the Bi-Flow gates into the crushing

Vertical Shaft Impactors Astec

Astec VSI crushers are available in both stationary and portable configurations and produce up to 500 tons per hour. With the ability to run in standard, semi-autogenous and fully

Valor® Vertical Shaft Impactor (VSI) Superior Industries

VSI Crushing Chamber Configurations SHOEANVIL (SOS) Open shoe table Feed sizes up to 8″ (203mm) Low to medium abrasion materials Steel on steel ROTORANVIL (ROS) Enclosed rotor and anvils Feed sizes to

VSI Crushers REMco

VSI Crushers Quality Vertical Shaft Impactors REMco Vertical Shaft Impactors are typically used in the third or fourth stage of crushing circuits. Feed rates are from 15 to 1500 TPH. Machine drive powers range from

Home REMco

REMco is an innovative crusher manufacturer with multiple patents on it VSI crushers which make its machines desirable for a systems integrator and OEMs for use in their plants. One such company is Australia’s

VSI Crushers Isc Vsi

ISC® VSI Crushers Click below for more information on current ISC® VSI Crusher Models and Capacities. Link To: ISC® VSI Crusher Models and Capacities Model 41-VSI ISC® Model41-VSI ISC® Model 41 VSI Texas

What Is A Vertical Shaft Impactor (VSI) Primer? Stedman

VSIs are excellent for everything from abrasive materials to waste and recycling applications. VSI Crushing Method The VSI is typically used after a primary or secondary

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

The VSI crushers are delivered with a fixed rotor speed depending of the crusher model. It is possible to order different pulleys and taper locks that will change the rotor speed. However, the fixed rotor speed is chosen with many years’ experience in mind and the benefits of changing to

Vertical Shaft Impactors Astec

Astec VSI crushers are available in both stationary and portable configurations and produce up to 500 tons per hour. With the ability to run in standard, semi-autogenous and fully autogenous configurations, our models meet the most stringent material specs, allowing you to meet the challenges of any job you face.

Texas Crusher Systems, Inc.

mpl CRUSHER SYSTEMS VERTICAL SHAFT IMPACT (VSI) CRUSHER Patented, Intelligent Design Rotor is closed with four (4) ports and has a patented balancing ring attached. This balancing ring allows

Canica 100 VSI MPS

Vertical Shaft Impactor. The 100 VSI features a dual motor drive with a capacity of up to 400 tph (365 mtph) Available in HD (Heavy Duty), HDS (Heavy Duty Sand), ROR (Rock on Rock), and ROS (Rock on Steel) configurations. (*Product color scheme represented is subject to change.)

Valor® Vertical Shaft Impactor (VSI) Superior

VSI Crushing Chamber Configurations SHOEANVIL (SOS) Open shoe table Feed sizes up to 8″ (203mm) Low to medium abrasion materials Steel on steel ROTORANVIL (ROS) Enclosed rotor and anvils Feed sizes to

Vertical Shaft Impact Crushers MEKA Crushing

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. The crushers are suitable for a wide range of applications including the production of high quality

Home REMco

We Sell The Broadest Range of VSI Crushers 100% American-Owned REMco Is your ONE-STOP FINE Crushing Solution Since 1983 Balance your plant production by turning stockpiled material into high-quality sand

PORTABLE VERTICAL IMPACT (VSI) CRUSHERS WITH

Portable Vertical Shaft Impact Crushers are wheel-mounted rock crushing machines, engineered for tertiary or quarternary crushing applications. Equipped with a vertical shaft impact crusher and a feed hopper with

VSI Crushers Isc Vsi

ISC® VSI Crushers Click below for more information on current ISC® VSI Crusher Models and Capacities. Link To: ISC® VSI Crusher Models and Capacities Model 41-VSI ISC® Model41-VSI ISC® Model 41 VSI Texas

CONSTMACH VSI Vertical Shaft Impact Crushers YouTube

CONSTMACH Vertical Shaft Impact Crushers are known as also SAND MAKING MACHINES and used as a tertiary stage crusher to get high ratio of fine material and t...

Capacity Tables REMco

To select the right crusher for your application, please refer to the Basic VSI circuit diagram. REMco impact crushers have two distinct capacities. As you can see from the chart, the sizes are measured at two different

Static Twister VS350 VSI Crusher Crushers Pilot Crushtec

This unique crushing action provides low wear costs, superior products and high reduction ratios. The Static Twister VS350 is mounted on a heavy-duty, free standing skid-frame and therefore does not require expensive foundations. There are three rotor options for the Twister VS350 3 port; 6 port; 4 port open table suited to differing

All Metso Corporation catalogs and technical brochures

Balance Crane Brochure. 8 Pages. Burner Systems for Rotary Kilns Brochure. (VSI) Crusher Orange Series Rotor Brochure. 16 Pages. ® MP 2500 Cone Crusher Brochure. Metso MX™ Multi-Action Cone Crusher Brochure. 5 Pages. ® NP13NP15 Impact Crusher Brochure.

Different types of crushers for distinctive needs Metso Outotec

2020年12月17日Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

The VSI crushers are delivered with a fixed rotor speed depending of the crusher model. It is possible to order different pulleys and taper locks that will change the rotor speed. However, the fixed rotor speed is chosen with many years’ experience in mind and the benefits of changing to

Canica 100 VSI MPS

Vertical Shaft Impactor. The 100 VSI features a dual motor drive with a capacity of up to 400 tph (365 mtph) Available in HD (Heavy Duty), HDS (Heavy Duty Sand), ROR (Rock on Rock), and ROS (Rock on Steel) configurations. (*Product color scheme represented is subject to change.)

Valor® Vertical Shaft Impactor (VSI) Superior

VSI Crushing Chamber Configurations SHOEANVIL (SOS) Open shoe table Feed sizes up to 8″ (203mm) Low to medium abrasion materials Steel on steel ROTORANVIL (ROS) Enclosed rotor and anvils Feed sizes to

Vertical Shaft Impact Crushers MEKA Crushing

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. The crushers are suitable for a wide range of applications including the production of high quality

Texas Crusher Systems, Inc.

mpl CRUSHER SYSTEMS VERTICAL SHAFT IMPACT (VSI) CRUSHER Patented, Intelligent Design Rotor is closed with four (4) ports and has a patented balancing ring attached. This balancing ring allows

PORTABLE VERTICAL IMPACT (VSI) CRUSHERS WITH

Portable Vertical Shaft Impact Crushers are wheel-mounted rock crushing machines, engineered for tertiary or quarternary crushing applications. Equipped with a vertical shaft impact crusher and a feed hopper with

VSI Crushers Isc Vsi

ISC® VSI Crushers Click below for more information on current ISC® VSI Crusher Models and Capacities. Link To: ISC® VSI Crusher Models and Capacities Model 41-VSI ISC® Model41-VSI ISC® Model 41 VSI Texas

CONSTMACH VSI Vertical Shaft Impact Crushers YouTube

CONSTMACH Vertical Shaft Impact Crushers are known as also SAND MAKING MACHINES and used as a tertiary stage crusher to get high ratio of fine material and t...

Capacity Tables REMco

To select the right crusher for your application, please refer to the Basic VSI circuit diagram. REMco impact crushers have two distinct capacities. As you can see from the chart, the sizes are measured at two different

Grinders REMco

Balance your plant production by turning stockpiled material into high-quality sand with the right FM, grading and finish to satisfy your customers' needs. VSI Crushers; Grinders; PROseries; Portables; Factory Parts;

Different types of crushers for distinctive needs Metso Outotec

2020年12月17日Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top

Static Twister VS350 VSI Crusher Crushers Pilot Crushtec

This unique crushing action provides low wear costs, superior products and high reduction ratios. The Static Twister VS350 is mounted on a heavy-duty, free standing skid-frame and therefore does not require expensive foundations. There are three rotor options for the Twister VS350 3 port; 6 port; 4 port open table suited to differing

CV229 VSI crusher — SRP

CV229 VSI impact crusher. CV229 VSI impact crusher is manufactured for tertiary and quaternary applications. It can handle anything from hard and abrasive rocks to soft, moist and even sticky materials. It's an efficient, versatile piece of equipment, designed to perform well with the most difficult materials. Email us Request a quote.

CV228 VSI crusher — SRP

CV228 VSI impact crusher. CV228 VSI impact crusher is manufactured for tertiary and quaternary applications. It can handle anything from hard and abrasive rocks to soft, moist and even sticky materials. It's an efficient, versatile piece of equipment, designed to perform well with the most difficult materials. Email us Request a quote.