Ball Mill To Grind Stone Project Aim In India

(PDF) SIZE REDUCTION BY GRINDING METHODS

The electric power consumption by this process run on ore mining and processing enterprises is variously estimated as a value from 5 to 20% of overall world electric

进一步探索

Mechanism of size reduction SlideShareMETHODS OF SIZE REDUCTION AND FACTORS AFFECPARTICLE SIZE REDUCTION TECHNIQUES SlideShareSize reduction of material using ball mill Labmonk(PDF) SIZE REDUCTION BY CRUSHING METHODS Res根据热度为您推荐•反馈

Ball mill Wikipedia

OverviewWorkingApplicationsDescriptionAdvantages of the ball millVarietiesSee also

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for

进一步探索

Lab Ball MillsBall Mills The Laboratory Store根据热度为您推荐•反馈

Grinding in Ball Mills: Modeling and Process Control

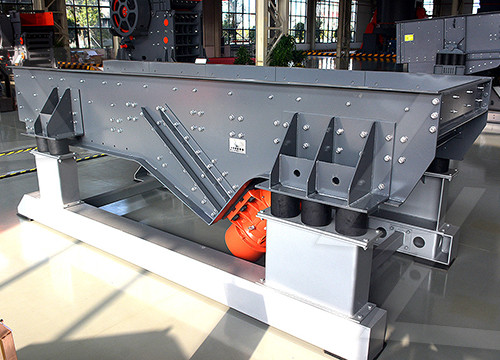

2012年6月1日The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 L-capacity grinding chamber made of an abrasion-resistant elastomer, put in vibrating motion by

Grinding Equipment, Ball Mill, Grinding Equipment Manufacturer

Grinding Equipment Continuous Ball Mill Batch Type Ball Mill Pulverizer Tube Mill Address 21/1, Alaknanda Society, Nr. Dental College Road, Manipur, Bopal Ghuma

Ball Mill Manufacturer, Ball mill Supplier, Exporter In India

Ball mills are special grinding machineries that are used in the industries for grinding and mixing diverse industrial raw-materials such as cement, lime stone, asphalt, ores and

Ball Mill Grinding Manufacturers India Ball Mill Grinding Plant

We offer Ball Mill Grinding Plant which consists of quality components, made by the latest technology as per industry norms. We are leading Ball Mill Grinding Plant

Laboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20 Kg Capacity

Ball Mill Manufacturers in India. Highest quality grinding media balls. Small / large size lab scale ball mill machine / grinding ball mills. Contact DirectlyGet Quotes!!

Grinding Media Ball Entrepreneur India

Grinding Media Ball Niir Project Consultancy Services (NPCS) through its network of project consultants in a wide range of business and technological disciplines is engaged

Continuous Ball Mill, Manufacturer, India

No.1 Continuous Ball Mill Manufacturer, supplier in india. It is a cylindrical grinder having three different compartments and screen. Replaceable liners or balls are fixed inside

Grinding Equipment, Ball Mill, Grinding Equipment Manufacturer

Grinding Equipment Continuous Ball Mill Batch Type Ball Mill Pulverizer Tube Mill Address 21/1, Alaknanda Society, Nr. Dental College Road, Manipur, Bopal Ghuma road, Ahmedabad 380058. Gujarat. Mobile No: +91 E-mail id: info@greenfieldtechprojects

Ball Mill Grinding Manufacturers India Ball Mill

We offer Ball Mill Grinding Plant which consists of quality components, made by the latest technology as per industry norms. We are leading Ball Mill Grinding Plant Manufacturers in India. Call Us: +91-990-900-6104.

Laboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20

Laboratory Ball Mill is primarily designed for grinding pigments. The material is ground at a specific speed by using a specific quantity of grinding media (steel balls) for a specific period. The equipment is used

Planetary Ball Mill PM 200 RETSCH short grinding times

The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml. The video shows wet grinding in the Planetary Ball Mill PM 100. The graphic shows the result of grinding barium titanate at 500 rpm in the PM 200. After 5 h of pulverization in heptane and oleic

Ball Charge and Grinding Efficiency Grinding

Ball mill grind is based on different principle; it has some attributes similar to SAG mill optimization. SAG mill breaks with stirring the kidney at optimized kidney specific gravity and maximum stir rate per mill

Grinding Media Ball Entrepreneur India

Grinding Media Ball. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. The grinding media is the balls, which may be made of steel (chrome steel), stainless steel, ceramic, or rubber. Grinding media, the objects used to refine

Steatite Ceramic Grinding Balls and Media Steatite ceramic grinding

Ball mills : Ball mills are the most commonly used mills to accomplish particle size reduction. A revolving vessel, the ‘drum’, lined with ceramic bricks contains grinding media and the raw material to be ground. Ball mills are classified into :- Batch typeContinuous type : Batch type ball mills are versatile and most widely used.

Christian Pfeiffer product overview Christian Pfeiffer

We design and build grinding plants and equip them with all the right features or auxiliaries. Our separators ensure even greater efficiency of your processes. And from the first idea to the last screw, we also design and build entire EP- or EPC-projects.

Ball Mill To Grind Stone Project Aim In India

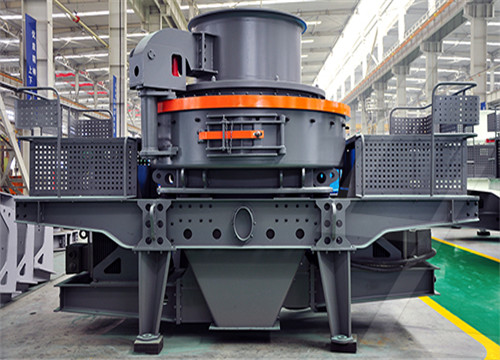

Home / Ball Mill To Grind Stone Project Aim In India. All Mobile crushing line Stationary crushing line Industrial grinding line. Limestone Sand Making Machine in Chongqing, China. Capacity: 120 T/H. Input Size: 25mm. 200TPH Bauxite Processing Production Line. Capacity: 120 T/H.

Name already in use github

sbm ball mills project indiagrinding ball mill unit project aelabworld.co.za project on grinding clinkers in ball mill india.VRM for clinker grinding and,in certain grinding lo

Bauxite Calcination Plant by Rotary Kiln with Fine Grinding Ball Mill

Calcined bauxite is available "run of kiln" i.e. uncrushed or in fractions and as ball milled powder according to customers’ requirements, in bulk or bagged. Calcined Bauxite is obtained by calcining (heating) superior grade Bauxite at high temperature (from 850 oC to 1600 oC). This removes moisture thereby increasing the alumina content.

CrusherGrinding Plant and Ball Mill Machine Manufacturer

About Us. Founded in the year 1995, we “Shreeji Engineering Works” are a dependable and famous Manufacturer of a broad range of Stone Crusher Plant, Jaw Crusher Machine, Pollution Control Plant, etc. + Read More. Nature of Business. Exporter and Manufacturer. Total Number of Employees. 26 to 50 People.

Mill (grinding) Wikipedia

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing. Industrial ball mills can be as large as 8.5 m (28 ft) in diameter with a 22 MW motor, [6] drawing

Grinding Equipment, Ball Mill, Grinding Equipment Manufacturer

Grinding Equipment Continuous Ball Mill Batch Type Ball Mill Pulverizer Tube Mill Address 21/1, Alaknanda Society, Nr. Dental College Road, Manipur, Bopal Ghuma road, Ahmedabad 380058. Gujarat. Mobile No: +91 E-mail id: info@greenfieldtechprojects

Ball Mill Grinding Manufacturers India Ball Mill

We offer Ball Mill Grinding Plant which consists of quality components, made by the latest technology as per industry norms. We are leading Ball Mill Grinding Plant Manufacturers in India. Call Us: +91-990-900-6104.

Laboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20

Laboratory Ball Mill is primarily designed for grinding pigments. The material is ground at a specific speed by using a specific quantity of grinding media (steel balls) for a specific period. The equipment is used

Planetary Ball Mill PM 200 RETSCH short grinding times

The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml. The video shows wet grinding in the Planetary Ball Mill PM 100. The graphic shows the result of grinding barium titanate at 500 rpm in the PM 200. After 5 h of pulverization in heptane and oleic

Bauxite Calcination Plant by Rotary Kiln with Fine

Calcined bauxite is available "run of kiln" i.e. uncrushed or in fractions and as ball milled powder according to customers’ requirements, in bulk or bagged. Calcined Bauxite is obtained by calcining (heating) superior

Ball Charge and Grinding Efficiency Grinding

Ball mill grind is based on different principle; it has some attributes similar to SAG mill optimization. SAG mill breaks with stirring the kidney at optimized kidney specific gravity and maximum stir rate per mill

Steatite Ceramic Grinding Balls and Media Steatite ceramic grinding

Ball mills : Ball mills are the most commonly used mills to accomplish particle size reduction. A revolving vessel, the ‘drum’, lined with ceramic bricks contains grinding media and the raw material to be ground. Ball mills are classified into :- Batch typeContinuous type : Batch type ball mills are versatile and most widely used.

Grinding Media Ball Entrepreneur India

Grinding Media Ball. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. The grinding media is the balls, which may be made of steel (chrome steel), stainless steel, ceramic, or rubber. Grinding media, the objects used to refine

jubiler-lukow.pl

Ball Mill To Grind Stone Dust China. Ball Mill To Grind Stone Project Aim In India Ball mill to grind stone project aim in india ore dressing ball mill projects for slag in india

CrusherGrinding Plant and Ball Mill Machine Manufacturer

About Us Founded in the year 1995, we “Shreeji Engineering Works” are a dependable and famous Manufacturer of a broad range of Stone Crusher Plant, Jaw Crusher Machine, Pollution Control Plant, etc. + Read More Nature of Business Exporter and Manufacturer Total Number of Employees 26 to 50 People Year of Establishment 1995 Legal Status of

Ball Mill an overview ScienceDirect Topics

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

Stationary inlet for ball mills

Stationary inlet for ball mills . Increases air flow through the mill Reduces power consumption Project Centre Denmark. A/S Vigerslev Allé 77. DK-2500 Valby Copenhagen Inc. 2040 Avenue C. Bethlehem, PA 18017-2188 Tel: +1 610-264-6011. Fax: +1 610-264-6170 E-mail: info-us@flsmidth. Project Centre India

Mill (grinding) Wikipedia

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing. Industrial ball mills can be as large as 8.5 m (28 ft) in diameter with a 22 MW motor, [6] drawing

- 氧化铁黄颚破

- 投资大理石厂需要多少钱

- 生产机械附件入什么科目

- 石英矿分子式

- wow铁矿石哪里多

- Impact Crusher Sub Bituminous?Coal Bangkabelitung?

- Process Study For A New Mini Cement Plant In New Zealand

- Calcium Carbonate Grinding Machine From Germany

- Floating Processing Equipment For Clay Riau?Indonesia

- 生产水设备

- 私人拉运建筑垃圾

- 生产砂浆产品的广东公司

- 采石场履带

- 特a级菱镁矿

- Highly Efficient Roll Crusher Stone Roll Crusher