Application Of Impact Crusher In Cement Raw Material Processing

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher

Cement Extraction and processing Britannica

根据热度为您推荐•反馈

Preparation Of Cement Raw Material Cement Mill, Cement Crusher

The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing. Crushing: the limestone and other materials are

ImpactCement Crusher Manufacturer Stedman

Stedman Machine has extensive experience crushing a variety of materials, a testing facility with full-sized equipment, and more than 10,000 test reports to help you determine what

Cement Crusher Crushers for Cement Plant AGICO

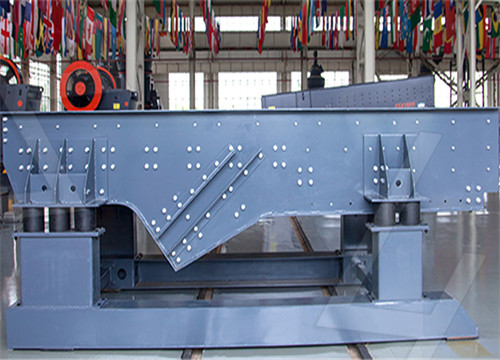

Impact Crusher Features: 1. Can be applied for various types of materials; 2. Fine product particle size; 3. Simple mechanical structure, compact and light; 4. Easy to repair and

Cement Crusher Crusher In Cement Plant AGICO Cement

In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay and other materials into proper size to facilitate the subsequent transportation and

Portland Cement Manufacturing Ordinary Portland

Impact Crusher Hammer Crusher Step 2: Pre-homogenization The pre-homogenization refers to the preliminary homogenization of cement raw materials and fuel raw materials through the application of scientific

Refurbishment of Cement Crusher Reconditioning of Impactor

Hydraulic impact crusher is primarily used for crushing of limestone. Grinding path is a component inside the impact crusher which gets totally worn out due to heavy impact

Impact crusher for sale AGICO Cement Plant

The impact crusher is a new and high-efficient cement crusher, with advantages of small size, simple structure, and large reduction ratio, less energy consumption, uniform

Preparation Of Cement Raw Material Cement Mill, Cement Crusher

The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing. Crushing: the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, cone crusher, jaw crusher, impact crusher, etc.

Cement Application Cement Types AGICO Different Types Of Cement

Impact Crusher; Four-roll Crusher; Industrial Dust Collector and then hardens in air and water. In modern life, cement, as an essential construction material, is widely used in civil construction, water conservancy, national defense, and other fields. The clinker calcination process realizes the conversion of cement raw meal to cement

Cement Raw MealHomogenization Process in The Cement

The raw meal preparation process of the cement industry includes four links: mining, pre-homogenization, grinding, and homogenization, which form the homogenization chain of raw meal preparation. Raw meal homogenization is the most important process link of the four, accounting for 40% of the homogenization task.

Raw Mill Raw Mill In Cement Plant AGICO Cement Raw Mill

Raw meal grinding is a vital link in the cement raw material preparation process. After the cement raw material is crushed, it will be sent into the raw mill for further grinding until a certain degree of fineness is reached, and then enter the clinker calcination process.

Refurbishment of Cement Crusher Reconditioning of Impactor

Hydraulic impact crusher is primarily used for crushing of limestone. Grinding path is a component inside the impact crusher which gets totally worn out due to heavy impact and abrasion. Impact crusher is critical for production of limestone (Raw material) for manufacturing cement, so any stoppage involves huge down time and production loss.

Raw Material Crushing Jaw Crusher|Hammer

Hammer Crusher. Scope of application: Hammer crusher is suitable for crushing minerals of various medium and hard brittle materials. The crushed material has a compressive strength of not more than 150 MPa

How to improve the Production Capacity of Impact Crusher?

In addition to break limestone, it can also process materials with compressive strength of 320 mpa and below, such as dolomite, marble, gypsum, shale, sandstone and so on. Impact crusher can adopt various types of configuration according to the type of raw materials, scale and finished material requirements.

What is Gypsum and How is it Used? mplcrusher

2023年3月10日Crushing system The gypsum raw material enters the crusher through the vibrating feeder, and be crushed into small particles less than 30mm. According to the size of gypsum raw materials and different production needs, different types and models of crushers can be selected.

Applied Sciences Free Full-Text Rock Material Recycling in

2020年3月17日All things considered, the preliminary concrete tests showed that concrete production using recycled aggregate is possible, also in the case of application of processed excavation rock material for all particle size classes. 5. Excavation Material Processing at the Brenner Base Tunnel. 5.1.

BHS crushing technology for Algeria's growing building materials

Building Materials Machinery Applications Mixers Crushers Testsconsulting After-sales Sales Showroom Mixers Crushers Testsconsulting After-sales

11.6 Portland Cement Manufacturing US EPA

1971年8月17日11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement

When the material is crushed and ground by impact, the material flows slowly from the feeding end to the discharging end to finish the grinding operation. Notes for raw mill in cement plant The raw mill is a kind of necessary cement equipment in the cement plant.

Hammer Crusher for Cement Raw Material

Scope of application: Hammer crusher is suitable for crushing minerals of various medium and hard brittle materials. The crushed material has a compressive strength of not more than 150 MPa and a humidity of not more than 15%. The materials to be crushed are coal, salt, white Asia, gypsum, alum, brick, tile, limestone and the like.

Crusher equipment and pulverizing mills for shale crushing processing

High-efficiency Equipment forArgillite Crushing Processing; Chert Impact Crusher and Grinding Mill Used in Chert Processing Plant; the raw material may be fed to one or two impact crushers, cone crushers or complete stone grinding mills in a sequence. Thereafter, the crushed stone is transmitted to the vibrating screen to the size gradation

11.6 Portland Cement Manufacturing US EPA

1971年8月17日11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of

Cement Raw MealHomogenization Process in The Cement

Cement raw meal is the raw material for producing cement clinker, which is prepared in a certain proportion after crushing and grinding. After being calcined in a rotary kiln, the raw meal is turned into the clinker. Raw meal in the stackyard The composition and shape of the raw meal may vary according to different cement production methods.

Raw Mill Raw Mill In Cement Plant AGICO Cement Raw Mill

Raw meal grinding is a vital link in the cement raw material preparation process. After the cement raw material is crushed, it will be sent into the raw mill for further grinding until a certain degree of fineness is reached, and then enter the clinker calcination process.

Refurbishment of Cement Crusher Reconditioning of Impactor

Hydraulic impact crusher is primarily used for crushing of limestone. Grinding path is a component inside the impact crusher which gets totally worn out due to heavy impact and abrasion. Impact crusher is critical for production of limestone (Raw material) for manufacturing cement, so any stoppage involves huge down time and production loss.

Raw Material Crushing Jaw Crusher|Hammer

Impact Crusher Applications: Widely used in building materials, ore crushing, and medium and fine materials in railways, highways, energy, transportation, energy, cement, mining, chemical and other industries.

How to improve the Production Capacity of Impact Crusher?

In addition to break limestone, it can also process materials with compressive strength of 320 mpa and below, such as dolomite, marble, gypsum, shale, sandstone and so on. Impact crusher can adopt various types of configuration according to the type of raw materials, scale and finished material requirements.

Hammer Crusher for Cement Raw Material

Scope of application: Hammer crusher is suitable for crushing minerals of various medium and hard brittle materials. The crushed material has a compressive strength of not more than 150 MPa and a humidity of not

What is Gypsum and How is it Used? mplcrusher

2023年3月10日Crushing system The gypsum raw material enters the crusher through the vibrating feeder, and be crushed into small particles less than 30mm. According to the size of gypsum raw materials and different production needs, different types and models of crushers can be selected.

Applied Sciences Free Full-Text Rock Material Recycling in

2020年3月17日All things considered, the preliminary concrete tests showed that concrete production using recycled aggregate is possible, also in the case of application of processed excavation rock material for all particle size classes. 5. Excavation Material Processing at the Brenner Base Tunnel. 5.1.

BHS crushing technology for Algeria's growing building materials

Building Materials Machinery Applications Mixers Crushers Testsconsulting After-sales Sales Showroom Mixers Crushers Testsconsulting After-sales

How Is Cement Produced in Cement Plants Cement Making Process

The proportioning of cement raw materials is not all the same but should be determined according to the actual situation. The proportion of raw materials of different specifications of cement is also different. Generally, the proportion of components in cement raw materials is 67-75% limestone, 10-15% clay, 0.5-1.5% iron ore and 8.5-11% coal.

Portland Cement Manufacturing Process In Cement Plant AGICO

The Portland cement manufacturing is a complex process which can be mainly divided into three parts: raw materials preparation, clinker calcination and cement grinding. Raw materials preparation: after materials are quarried, they need to undergo crushing, blending, grinding and storage four processes to finish the raw materials preparation

Crusher equipment and pulverizing mills for shale crushing processing

High-efficiency Equipment forArgillite Crushing Processing; Chert Impact Crusher and Grinding Mill Used in Chert Processing Plant; the raw material may be fed to one or two impact crushers, cone crushers or complete stone grinding mills in a sequence. Thereafter, the crushed stone is transmitted to the vibrating screen to the size gradation