Ultra Fine Crusher Refractory Gold

Ultra fine milling for the recovery of refractory gold

1991年1月1日Ultra-fine milling (UFM), producing particles with sizes in the range of 1–20 µm, has been proven to be able to expose the gold from its carrier minerals and hence

Gold recovery optimization of a refractory concentrate by

2011年5月1日This laboratory work presents a study of the effect of ultrafine grinding on the gold recovery of a highly refractory gold concentrate. The particle size of the

[PDF] Ultra Fine Grinding-A Practical Alternative to Oxidative

Published 2003 Materials Science Since early 2001, Kalgoorlie Consolidated Gold Mines (K) has successfully operated an ultra fine grinding (UFG) circuit to supplement its

Ultra Fine Grinding A Practical Alternative to Oxidative

Refractory Gold Ores S. Ellis Kalgoorlie Consolidated Gold Mines Kalgoorlie, WA. Abstract Since early 2001, Kalgoorlie Consolidated Gold Mines (K) has successfully

(PDF) EFFECT OF ULTRA-FINE GRINDING ON

2019年4月16日This refractory behaviour can vary from mild to severe with gold recoveries of 85% down to less than 30% [1].A common cause of refractoriness is

Ultra Fine Grinding A Practical Alternative to Oxidative Treatment

Since early-2001, Kalgoorlie Consolidated Gold Mines (K) has successfully operated an ultra fine grinding (UFG) circuit to supplement its roaster capacity for the treatment of

Ultra fine milling for the recovery of refractory gold

Ultra fine milling for the recovery of refractory gold @article{Corrans1991UltraFM, title={Ultra fine milling for the recovery of refractory gold}, author={Ian James Corrans

Development of ultrafine grinding at Kalgoorlie

2003年11月1日The process involves the fine grinding of refractory pyritic concentrate to 10 μm followed by direct cyanide leaching for gold recovery. By this means, gold can be

Refractory gold reserves: Challenges and opportunities

2021年3月23日Gold miners are facing a reserves crisis, and what is left in the ground is becoming more and more challenging to process.Refractory gold reserves, which

Refractory gold reserves: Challenges and opportunities for a key

2021年3月23日Refractory gold reserves, which require more sophisticated treatment methods in order to achieve oxide-ore recovery rates, correspond to 24 percent of current gold reserves and 22 percent of gold resources worldwide (Exhibit 1).

Ultra fine milling for the recovery of refractory gold

1991年1月1日Ultra-fine milling (UFM), producing particles with sizes in the range of 1–20 µm, has been proven to be able to expose the gold from its carrier minerals and hence significantly improve gold flotation and cyanidation or lower the temperature and pressure required for the subsequent oxidation process (Celep et al., 2011; Corrans and Angove,

Optimization of some parameters of stirred mill for ultra-fine

2011年3月10日Section snip Materials used. An antimonial refractory gold/silver ore sample obtained from Akoluk (Ordu-Turkey) was used in this work. The ore sample was crushed down to − 4 mm using jaw and rolls crushers, and riffled to obtain 1 kg representative sub-samples.These were then ground in laboratory rod mill at 50% pulp

Gold recovery optimization of a refractory concentrate by

2011年5月1日This laboratory work presents a study of the effect of ultrafine grinding on the gold recovery of a highly refractory gold concentrate. The particle size of the concentrate was P80 = 46 µm and the main species present were quartz (28.58%), dolomite (25.63%), pyrite (20.93%), arsenopyrite (15.39%) and 112 g/t gold. S., 2003, “Ultra

Ultra Fine Grinding A Practical Alternative to Oxidative

Not all refractory gold ores give a large recovery improvement after fine milling. Gold locked in arsenopyrite for example does not achieve the same gold recovery as gold disseminated in pyrite due to the smaller gold particle size of the locked gold (Figure 5). Figure 5. Gold Recovery of Arsenopyrite and Pyrite Ores 50 55 60 65 70 75 80 85 90

(PDF) Improvement of Cyanidation of Antimonial Refractory Gold

2010年1月1日Ultra fine milling (UFM) as an alternative to chemical or biological pretreatments can be utilised to engender the exposure of encapsulated gold or silver particles (Adams, 2005) to cyanide...

Refractory Gold Technology

refractory gold processes: the Sao Bento Mineracao plant in Brazil, operating on arsenopyrite-pyrite-pyrrhotite concentrates since 1986; Many gold ores and concentrates contain fine grained gold locked within sulphide minerals, such as pyrite and/or arsenopyrite, unavailable for recovery by conventional leaching. In Sherritt’s gold

(PDF) EFFECT OF ULTRA-FINE GRINDING ON EXTRACTION OF GOLD

2019年4月16日In this study, the effects of ultra-fine grinding (from 27 µm (d 80,as-received) to 7.5 µm), cyanide concentration (2-5 g/L NaCN) and pulp density (30-50% w/w) on the rate and extent of...

Ultra Fine Grinding A Practical Alternative to Oxidative

Since early-2001, Kalgoorlie Consolidated Gold Mines (K) has successfully operated an ultra fine grinding (UFG) circuit to supplement its roaster capacity for the treatment of the refractory gold flotation concentrate. A second UFG mill was installed in 2002 taking the total UFG capacity to over 20 tph while grinding to 11 to 12 microns and achieving over

Table 1 from Ultra Fine Grinding-A Practical Alternative to

Corpus ID: ; Ultra Fine Grinding-A Practical Alternative to Oxidative Treatment of Refractory Gold Ores @inproceedings{Kalgoorlie2003UltraFG, title={Ultra Fine Grinding-A Practical Alternative to Oxidative Treatment of Refractory Gold Ores}, author={S. Ellis Kalgoorlie}, year={2003} }

Ultra fine milling for the recovery of refractory gold

Ultra fine milling for the recovery of refractory gold @article{Corrans1991UltraFM, title={Ultra fine milling for the recovery of refractory gold}, author={Ian James Corrans and Janice Angove}, journal={Minerals Engineering}, year={1991}, volume={4}, pages={763-776} } I. Corrans, J. Angove; Published 1991; Materials Science; Minerals Engineering

Ultrafine: soil sampling for gold exploration CSIRO

We developed the UltraFine+ process for particles less than two microns in size. The process involves a physical step to retain the fine microparticles and a chemical step to test for the presence of gold and other elements.

sbmchina/sbm fabrike za ultra fine mill.md at main github

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

crusher/sbm refractory gold ore milling in oregon.md at main

Contribute to yunan88/crusher development by creating an account on GitHub.

Optimization of some parameters of stirred mill for ultra-fine

2011年3月10日Section snip Materials used. An antimonial refractory gold/silver ore sample obtained from Akoluk (Ordu-Turkey) was used in this work. The ore sample was crushed down to − 4 mm using jaw and rolls crushers, and riffled to obtain 1 kg representative sub-samples.These were then ground in laboratory rod mill at 50% pulp

Optimization of some parameters of stirred mill for ultra-fine

2011年3月10日An antimonial refractory gold/silver ore sample obtained from Akoluk (Ordu-Turkey) was used in this work. The ore sample was crushed down to − 4 mm using jaw and rolls crushers, and riffled to obtain 1 kg representative sub-samples.These were then ground in laboratory rod mill at 50% pulp density for 40 min (80% passing size, d 80

Gold recovery optimization of a refractory concentrate by

2011年5月1日This laboratory work presents a study of the effect of ultrafine grinding on the gold recovery of a highly refractory gold concentrate. The particle size of the concentrate was P 80 = 46 µm and the main species present were quartz (28.58%), dolomite (25.63%), pyrite (20.93%), arsenopyrite (15.39%) and 112 g/t gold.

Ultra Fine Grinding A Practical Alternative to Oxidative

Not all refractory gold ores give a large recovery improvement after fine milling. Gold locked in arsenopyrite for example does not achieve the same gold recovery as gold disseminated in pyrite due to the smaller gold particle size of the locked gold (Figure 5). Figure 5. Gold Recovery of Arsenopyrite and Pyrite Ores 50 55 60 65 70 75 80 85 90

Refractory Gold Technology

refractory gold processes: the Sao Bento Mineracao plant in Brazil, operating on arsenopyrite-pyrite-pyrrhotite concentrates since 1986; Many gold ores and concentrates contain fine grained gold locked within sulphide minerals, such as pyrite and/or arsenopyrite, unavailable for recovery by conventional leaching. In Sherritt’s gold

Ultra Fine Grinding A Practical Alternative to Oxidative

Since early-2001, Kalgoorlie Consolidated Gold Mines (K) has successfully operated an ultra fine grinding (UFG) circuit to supplement its roaster capacity for the treatment of the refractory gold flotation concentrate. A second UFG mill was installed in 2002 taking the total UFG capacity to over 20 tph while grinding to 11 to 12 microns and achieving over

Table 2 from Ultra Fine Grinding-A Practical Alternative to

Corpus ID: ; Ultra Fine Grinding-A Practical Alternative to Oxidative Treatment of Refractory Gold Ores @inproceedings{Kalgoorlie2003UltraFG, title={Ultra Fine Grinding-A Practical Alternative to Oxidative Treatment of Refractory Gold Ores}, author={S. Ellis Kalgoorlie}, year={2003} }

Ultra fine milling for the recovery of refractory gold

Ultra fine milling for the recovery of refractory gold I. Corrans, J. Angove Published 1991 Materials Science Minerals Engineering View via Publisher Save to Library Create Alert Cite 55 Citations Citation Type More Filters FOR PROCESSING OF REFRACTORY GOLD-CONTAINING CONCENTRATES BASED ON ULTRAFINE GRINDING AND

Mineralogical Characteristics of a Micro-Fine and

2018年1月1日Among these refractory gold ores, sulfur and micro-grained native gold o res represent a significant challenge, since they are not amenable to gold recovery by direct cyanidation. The...

Ultrafine: soil sampling for gold exploration CSIRO

We developed the UltraFine+ process for particles less than two microns in size. The process involves a physical step to retain the fine microparticles and a chemical step to test for the presence of gold and other elements.

Beneficiation of Gold and Silver Ores SpringerLink

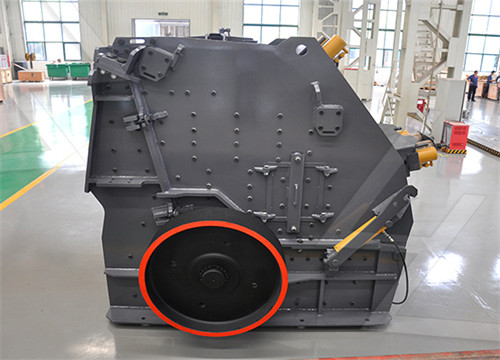

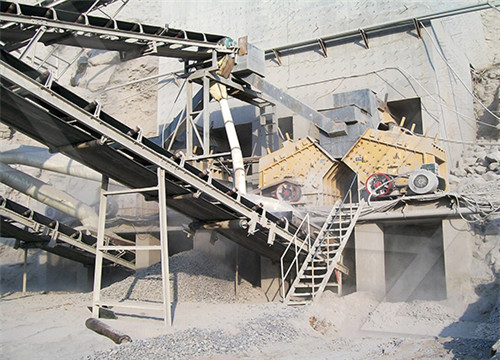

2019年12月15日The selection of the right crushers and crusher flow sheet is dependent on the upstream mining method and blasting characteristics and the downstream process requirements. Refractory gold ores commonly contain free gold, submicroscopic gold and J. Kelly. 2014. Super-fine crushing to ultra-fine size the “IMP” super-fine crusher.

ultra fine milling for the recovery refractory gold

Fine Milling Ore ultra fine milling for the recovery refractory gold . ore crushing machine mpl Ultra Fine Gold Quartz Mill in the word,We can give you best Chat Now Ultra fine milling for the recovery of refractory gold "Ultra fine grinding (UFG) can be suitably practiced to improve metal extractions from those ores that contain the

sbmchina/sbm fabrike za ultra fine mill.md at main github

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Engineering Services MetallurgistMineral Processing Engineer

Grinding SAG/Ball/Rod mills, Ultra Fine Grinding. Solid/Liquid Separation filtration, clarification, thickening. Leach bioleach, acid leach and pressure leach experience in gold and a variety of base metals. Tailings Disposal experience with tailings detoxification, thickening and impoundment.