High Frequency Screen For Iron Ore High Output

High Frequency Screens Astec

Astec high frequency screens utilize high-speed vibration, from 3600 4200 RPM, directly induced to the screen media, allowing for increased stratification and material separation. The directly-induced vibration improves screen efficiency at high production rates

进一步探索

TCI Manufacturing › High Frequency ScreensMobile High Frequency Screen Plants AstecKpi-Jci High Frequency Screens Alta Equipment6′ X 12′ PEP VARI-VIBE 2 HIGH FREQUENCY SCREENUsed High Frequency Screens for sale. MSL equipmentm根据热度为您推荐•反馈

High-frequency vibrating screens Wikipedia

OverviewRange of applicationsAdvantages and limitationsAvailable designsMain process characteristicsCharacteristics assessmentPossible heuristics to be used during design of the processPost-treatment systems

High-frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry. They are used to separate feeds containing solid and crushed ores down to less than 200 μm in size, and are applicable to both perfectly wetted and dried feed. The frequency of the screen is mainly controlled by an electromagnetic vibrator which is mounted above and directly connected to the screening surface. Its high-frequency characteristics differe

Fangyuan FY-HVS Multi-deck High Frequency Screen is widely

Fangyuan FY-HVS Multi-deck High Frequency Screen is widely used in iron ore separation with accurate classification and high screening efficiency. Our clients

High Frequency Screen,High Frequency Mineral Screen,High

High Frequency Screen. High frequency screen is superior for high efficiency, small amplitude, and high screening frequency. It is effective screening equipment for fine

10 Most Popular Iron Ore Beneficiation Machines mpl

2022年3月22日During the classification of iron ore, the vibration frequency of the screen surface is 50Hz, the amplitude is 0 to 2 mm, and the vibration intensity is 8 to 10 times of

High Frequency Vibrating Ore Screen,High Frequency Mineral

The Advantages and Benefits of High Frequency Screen: It differs from the conventional screens with breaking of the surface tension of pulp and high speed vibration on sieve

high frequency screen|high frequency vibrating screen

The main working part of the high frequency screen is a rotor with a hammer (also called a hammerhead). The motor drives the rotor to do high-speed rotation in the crushing

High Frequency Vibrating Ore Screen,High Frequency

High Frequency Screen. Processing ability: 15–48 t/h Screen area: 4.5–8.1 m2 Applied material:iron ore, tin, tungsten, tantalum, niobium, etc

High Frequency Screen|High frequency mineral

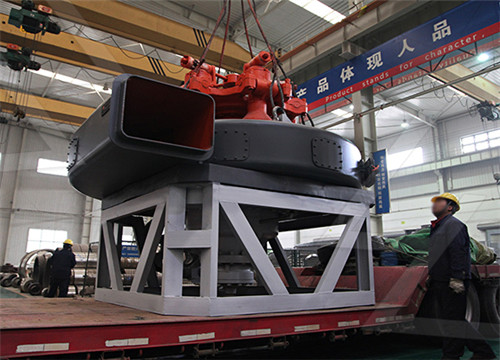

The Component Parts and Function of High Frequency Screen: High frequency screen is composed of exciter, pulp distributor, screen frame, rack, hanging spring and screen mesh. High frequency vibration fine

High frequency screen,High frequency vibrating ore

High frequency vibrating ore screen consists of vibration exciter, ore pulp distributor, screen frame, machine frame, suspension springs and sieve, etc. Timely screening

Iron Ore Statistics and Information U.S. Geological Survey

Almost all (98%) iron ore is used in steelmaking. Iron ore is mined in about 50 countries. The seven largest of these producing countries account for about three-quarters of total world production. Australia and Brazil together dominate the world's iron ore exports, each having about one-third of total exports.

High Frequency Screen,High Frequency Mineral Screen,High Frequency Ore

High Frequency Screen. High frequency screen is superior for high efficiency, small amplitude, and high screening frequency. It is effective screening equipment for fine material, widely used for screening of iron ore, tin,

10 Most Popular Iron Ore Beneficiation Machines mpl

2022年3月22日During the classification of iron ore, the vibration frequency of the screen surface is 50Hz, the amplitude is 0 to 2 mm, and the vibration intensity is 8 to 10 times of the acceleration of gravity, which is 2 to 3 times of the vibration intensity of the

High-frequency Screen sbmchina

High-frequency screen is a good choice for screening and grading the fine particles of mineral ores. This machine has wide application in iron ore, tin ore, tungsten ore, tantalum ore, dolomite sand and some other kinds of mining dressing plants' screening and

High-grade iron ore, metallics in focus to enable DRI, low

2022年6月7日"Very high-quality iron ore pellets are required for the new steelmaking process via SALCOS involving direct reduction plants and electric arc furnaces," LKAB said in a statement. Rio Tinto and other steel and mining groups have highlighted the need to adapt processes for DRI plants which have traditionally run on reformed natural gas as

High Frequency Screen|High frequency mineral screen|High frequency ore

The Component Parts and Function of High Frequency Screen: High frequency screen is composed of exciter, pulp distributor, screen frame, rack, hanging spring and screen mesh. High frequency vibration fine screen is called high frequency screen for short and it is a type of classifying machine used in the ore dressing plant.

High Frequency Vibrating Ore Screen,High Frequency Mineral Screen,High

The Advantages and Benefits of High Frequency Screen: It differs from the conventional screens with breaking of the surface tension of pulp and high speed vibration on sieve cover and accelerates the separating of large-density useful mines, and it increases the contacting probability of the materials smaller than output granularity and the

sbm/sbm high output ore linear vibrating screen.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Iron ore Wikipedia

Lower-grade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, high-quality fine ore powders, are known as fines. Magnetite. Magnetite is magnetic, and hence easily

sbm/sbm permanent magnetic rotary drum for chrome ore high frequency

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Iron ore hits 7-year high after Vale lowers output forecast

2020年12月2日The price of iron ore reached a seven-year high on Wednesday after one of the biggest global producers of the material lowered its output forecasts, giving further momentum to what has been...

High Frequency Screen-Ore dressing machine Henan Fote

High frequency screen has high efficiency, small amplitude and high screening frequency. It is an efficient machine widely used for the wet type and dry type screening, classification and dehydration of all kinds of fine particles such as iron, tin, tungsten, tantalum, niobium sand.

Iron Ore Screen manufacturerssuppliers made-in-china

Iron Ore Screen 22,687 products found from 613 Iron Ore Screen manufacturerssuppliers. Product List ; Supplier List; View: List View

High frequency vibration fine screen Jinpeng Mining

High-frequency Screen is an efficient equipment which can calssify ultrafine mineral, it has following advantages:high efficiency,high producing ability,low energy cost, it can efficiently prevent excessively grinding, it can greatly prevent the excessively grinding of useful minerals, and improve the recycling rate of mineral processing, so it is widely used to

High-frequency Screen sbmchina

High-frequency screen is a good choice for screening and grading the fine particles of mineral ores. This machine has wide application in iron ore, tin ore, tungsten ore, tantalum ore, dolomite sand and some other kinds of mining dressing plants' screening and

High Frequency Screen,High Frequency Mineral Screen,High Frequency Ore

High Frequency Screen. High frequency screen is superior for high efficiency, small amplitude, and high screening frequency. It is effective screening equipment for fine material, widely used for screening of iron ore, tin,

sbm/sbm high output ore linear vibrating screen.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

High Frequency Vibrating Ore Screen,High Frequency Mineral Screen,High

The Advantages and Benefits of High Frequency Screen: It differs from the conventional screens with breaking of the surface tension of pulp and high speed vibration on sieve cover and accelerates the separating of large-density useful mines, and it increases the contacting probability of the materials smaller than output granularity and the

Vale to increase high-grade iron ore output in tightening market

2023年2月27日Vale said its output of high-grade agglomerates is set to reach 50 million to 55 million tonnes in 2026, up from 32 million in 2022. Vale to increase high-grade iron ore output in tightening

Iron ore Wikipedia

The two main methods of recycling iron from iron ore tailings are magnetizing roasting and direct reduction. Magnetizing roasting uses temperatures between 700 and 900 °C for a time of under 1 hour to produce an iron concentrate (Fe 3 O 4) to be used for iron smelting.

Iron Ore Screen manufacturerssuppliers made-in-china

Iron Ore Screen 22,687 products found from 613 Iron Ore Screen manufacturerssuppliers. Product List ; Supplier List; View: List View

High-grade iron ore, metallics in focus to enable DRI, low

2022年6月7日"Very high-quality iron ore pellets are required for the new steelmaking process via SALCOS involving direct reduction plants and electric arc furnaces," LKAB said in a statement. Rio Tinto and other steel and mining groups have highlighted the need to adapt processes for DRI plants which have traditionally run on reformed natural gas as

sbm/sbm permanent magnetic rotary drum for chrome ore high frequency

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Iron ore hits 7-year high after Vale lowers output forecast

2020年12月2日The price of iron ore reached a seven-year high on Wednesday after one of the biggest global producers of the material lowered its output forecasts, giving further momentum to what has been...

High frequency vibration fine screen Jinpeng Mining

High-frequency Screen is an efficient equipment which can calssify ultrafine mineral, it has following advantages:high efficiency,high producing ability,low energy cost, it can efficiently prevent excessively grinding, it can greatly prevent the excessively grinding of useful minerals, and improve the recycling rate of mineral processing, so it is widely used to

High Frequency Screen Mining, Crushing, Grinding, Beneficiation

This is resulting in better separation conditions for materials smaller than the separation size to pass through the screen mesh with slurry to be the screened products. APPLICATIONS: Mining,coal,chemical,,fertilizer,etc. PROCESSED MATERIALS: iron ore,zinc ore,tin ore,tungsten ore,etc. SPECIFICATIONS

High Frequency Screen-Ore dressing machine Henan Fote

High frequency screen has high efficiency, small amplitude and high screening frequency. It is an efficient machine widely used for the wet type and dry type screening, classification and dehydration of all kinds of fine particles such as iron, tin, tungsten, tantalum, niobium sand.

mining vibration screens MiningQuarry Plant

2013年4月4日High-frequency screen consists of vibration exciter, ore pulp distributor, screen frame, machine frame, Two-Mass Vibratory Screens for Mining / Minerals Vibrating Screens WMB Mining

- Mobile Rock Crusher Afghanistan

- China Professional Manufacturer Of Chrome Casting Grinding Ball

- 石场是什么单位管理

- 建筑矿山机械

- 2011 Hot Impact Crusher With Factory

- 加工累托石的设备

- 加工机制沙的设备

- 钒矿 加工技术

- 120TPH反击式石料破碎机

- Used Ready Mix Concrete Plant Manufacturer

- 移动破碎机德国

- 建筑废品回收

- 板式给矿机不出粉怎么办

- 做石绵线的机器

- Posho Mills Manufacturers In Kenya