Function Of Machine In Making Limestone To Cement

2 Major Roles of Limestone in Cement Manufacturing

2023年2月15日The answer is the cement industry. Limestone plays two major roles in the cement manufacturing process, one is used as a raw material for cement clinker,

进一步探索

Understanding Limestone in Cement Concrete ConstructThe role of calcium carbonate in cement hydration Science根据热度为您推荐•反馈

Cement Extraction and processing Britannica

根据热度为您推荐•反馈

Industrial production of limestone calcined clay cement:

2019年3月18日The reduction of the clinker factor in cement has emerged as the most promising solution to reduce carbon dioxide (CO 2) emissions and to improve

Understanding Limestone in Cement Concrete

2015年3月26日The limestone acts as a seed crystal for the cement, better distributing the reaction products and increasing the reactivity of the cement. As there is always

How is concrete made from limestone? Shelly Company

2014年1月29日To make Portland cement—the most common type of cement—powdered limestone is heated in a rotary kiln. As a source of calcium, it joins with powdered clay to produce a product called clinker,

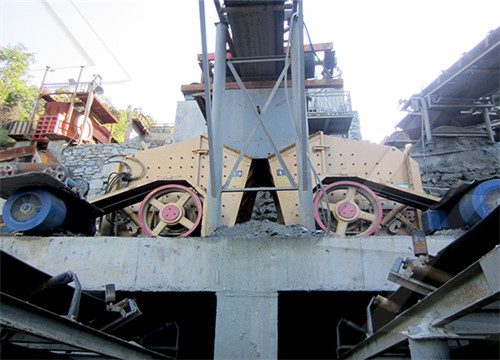

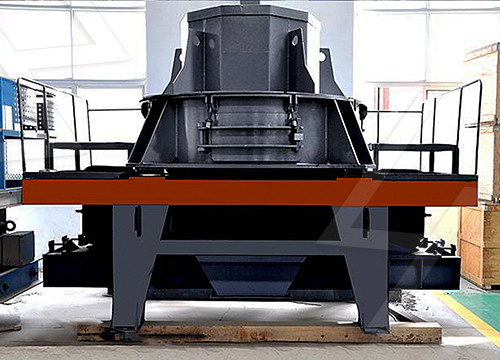

Cement Euipment Overview Cement Making Machines

2019年9月27日Cement mill has two functions of the cement production line. Firstly, cement mill is used to grind the crushed material into fine size before clinker production.

How Is Cement Produced in Cement Plants Cement

The cyclone preheater is one of the core equipment for dry process cement production, which consists of a series of vertical cyclones locate on several stages. Inside the

How Cement is Made Cement Manufacturing Process

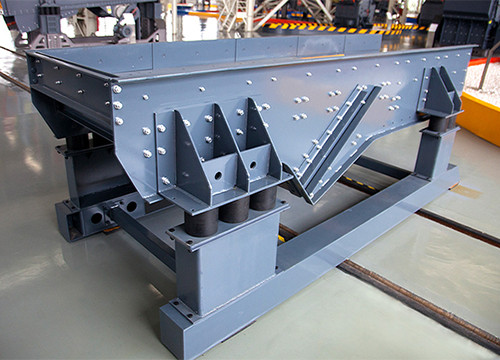

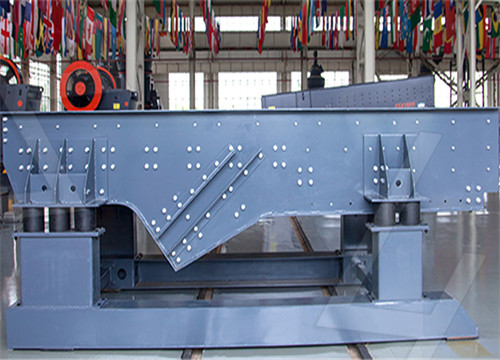

Stage 2: Grinding, Proportioning, and Blending The crushed raw ingredients are made ready for the cement-making process in the kiln by combining them with additives and grinding

function of machine in making limestone to cement

making cement from limestone beltconveyers.net, Home > Crusher Machine > making cement from limestone. making cement from limestone. Post at: Mar 22, 2001

Materials Special Issue : Advances in Limestone Calcined Clay Cement

2022年11月20日Making limestone calcined clay cement (LC 3) is a practical choice because clays and limestone are abundantly available all over the world. This Special Issue will cover the rapidly growing body of knowledge about LC 3, the background to the development of LC 3, detailed reviews of the chemistry of LC 3 hydration and synthesis,

Cement Extraction and processing Britannica

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are

Portland cement Britannica

2023年2月23日hydraulic cement clinker semidry process portland cement, binding material in the form of a finely ground powder, usually gray, that is manufactured by burning and grinding a mixture of limestone and clay or limestone and shale.

How Cement is Made Cement Manufacturing Process

Stage 2: Grinding, Proportioning, and Blending The crushed raw ingredients are made ready for the cement-making process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture. The composition of cement is proportioned here depending on the desired properties of the cement. Generally, limestone is 80%, and

8 Main Cement IngredientsTheir Functions Civil

The main features of these cement ingredients along with their functions and usefulness or harmfulness are given below: Lime: Lime is calcium oxide or calcium hydroxide. The presence of lime in a sufficient quantity is

function of machine in making limestone to cement

making cement from limestone beltconveyers.net, Home > Crusher Machine > making cement from limestone. making cement from limestone. Post at: Mar 22, 2001 Free Online Library: Making limestone concrete. Go to Product Center. role of limestone in cement industry mpl, sand making machine,belt conveyor,sand

Effect of Functional Polycarboxylic Acid Superplasticizers on

2020年8月5日Modern engineering practices require that polycarboxylic acid high-performance superplasticizers have good adaptability to various environments and materials, which indicates the importance of producing functional polycarboxylic acid superplasticizers with a variety of functions. Therefore, in this work, a functional

Particle-bed 3D printing by selective cement activation Influence

The materials used for this study are commercially available products. The binder in all mixtures is a CEM I 52.5 N-SE cement with a density of 3.1 g/cm 3 and a median particle size of d 50 = 11 μm and an upper particle size limit of d 90 = 29 μm. As aggregate, two types of quartz sand (QS, SiO 2 > 98 %) with a density of 2.65 g/cm 3 are used: a finer

LimestoneCement LinkedIn

2020年2月16日It has two basic functions in steel making, first to lower the temperature of melting and second, to form calcium silicate which comes out as a slag, as it combines with silica in iron ore. For...

New approach suggests path to emissions-free cement

2019年9月16日Caption: In a demonstration of the basic chemical reactions used in the new process, electrolysis takes place in neutral water. Dyes show how acid (pink) and base (purple) are produced at the

Electrolysis technique makes cement CO2 emission-free New

2019年9月17日The cement making process as described in the article is out of sequence. The first step is to heat limestone to 2700 degrees F to break the bond of the water that holds the limestone together.

Cement manufacturing process: Step-by-step guide

2020年7月20日Step 4:Cement grinding and storage. Clinker and gypsum for Ordinary Portland Cement (OPC) limestone for limestone cement, and slag for slag cement are all extracted from their respective hoppers and fed to the cement mills. The ball mill grinds the feed to a fine powder in two chambers, namely the first and second chambers.

Cement has a carbon problem. Here are some concrete solutions.

2019年11月20日To make cement, you have to heat limestone to nearly 1,500 degrees C. Unfortunately, the most efficient way to get a cement kiln that hot is to burn lots of coal, Making cement green.

Materials Special Issue : Advances in Limestone Calcined Clay Cement

2022年11月20日Making limestone calcined clay cement (LC 3) is a practical choice because clays and limestone are abundantly available all over the world. This Special Issue will cover the rapidly growing body of knowledge about LC 3, the background to the development of LC 3, detailed reviews of the chemistry of LC 3 hydration and synthesis,

Cement Extraction and processing Britannica

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are

Electrolysis technique makes cement CO2 emission

2019年9月17日The cement making process as described in the article is out of sequence. The first step is to heat limestone to 2700 degrees F to break the bond of the water that holds the limestone together.

How Cement is Made Cement Manufacturing Process

Stage 2: Grinding, Proportioning, and Blending The crushed raw ingredients are made ready for the cement-making process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture. The composition of cement is proportioned here depending on the desired properties of the cement. Generally, limestone is 80%, and

8 Main Cement IngredientsTheir Functions Civil

Functions of Cement Ingredients The main features of these cement ingredients along with their functions and usefulness or harmfulness are given below: Lime: Lime is calcium oxide or calcium hydroxide. The

function of machine in making limestone to cement

making cement from limestone beltconveyers.net, Home > Crusher Machine > making cement from limestone. making cement from limestone. Post at: Mar 22, 2001 Free Online Library: Making limestone concrete. Go to Product Center. role of limestone in cement industry mpl, sand making machine,belt conveyor,sand

Effect of Functional Polycarboxylic Acid Superplasticizers on

2020年8月5日The polycarboxylic acid-based high-performance water-reducing agent products provided in this article can be used in high-strength and high-performance concrete, such as bridges, high-rise buildings, high-speed railways, nuclear power plants, hydropower stations, etc., which can improve the working performance, mechanical

Particle-bed 3D printing by selective cement activation Influence

The materials used for this study are commercially available products. The binder in all mixtures is a CEM I 52.5 N-SE cement with a density of 3.1 g/cm 3 and a median particle size of d 50 = 11 μm and an upper particle size limit of d 90 = 29 μm. As aggregate, two types of quartz sand (QS, SiO 2 > 98 %) with a density of 2.65 g/cm 3 are used: a finer

New approach suggests path to emissions-free cement

2019年9月16日The process produces carbon dioxide in two different ways: from the burning of the coal, and from gases released from the limestone during the heating. Each of these produces roughly equal

Cement has a carbon problem. Here are some

2019年11月20日To make cement, you have to heat limestone to nearly 1,500 degrees C. Unfortunately, the most efficient way to get a cement kiln that hot is to burn lots of coal, which, along with other...

Concrete, a Centuries-Old Material, Gets a New Recipe

2020年8月11日The cement industry is promoting Portland-limestone cement, which reduces carbon 10 percent, according to the Portland Cement Association, a trade group. Several new ways to make concrete greener

Cement manufacturing process: Step-by-step guide

2020年7月20日Step 4:Cement grinding and storage. Clinker and gypsum for Ordinary Portland Cement (OPC) limestone for limestone cement, and slag for slag cement are all extracted from their respective hoppers and fed to the cement mills. The ball mill grinds the feed to a fine powder in two chambers, namely the first and second chambers.